Our range of services

In the Fourth Industrial Revolution, networked technologies are on the rise, thus increasing the amount of data that needs to be processed quickly and inline. In production metrology, the importance of real-time signal processing, in particular, is increasing.

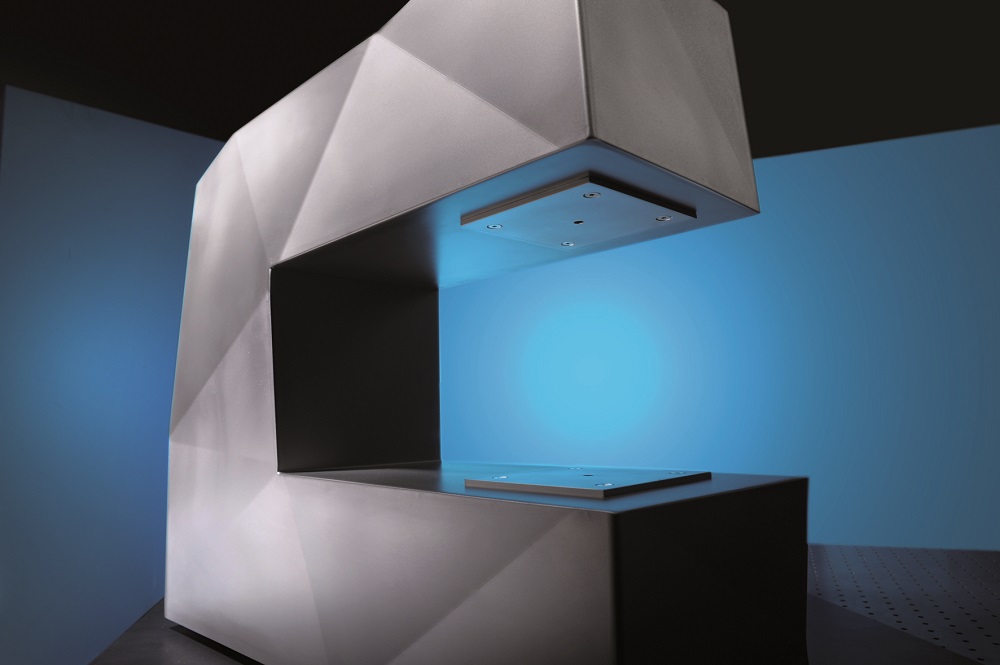

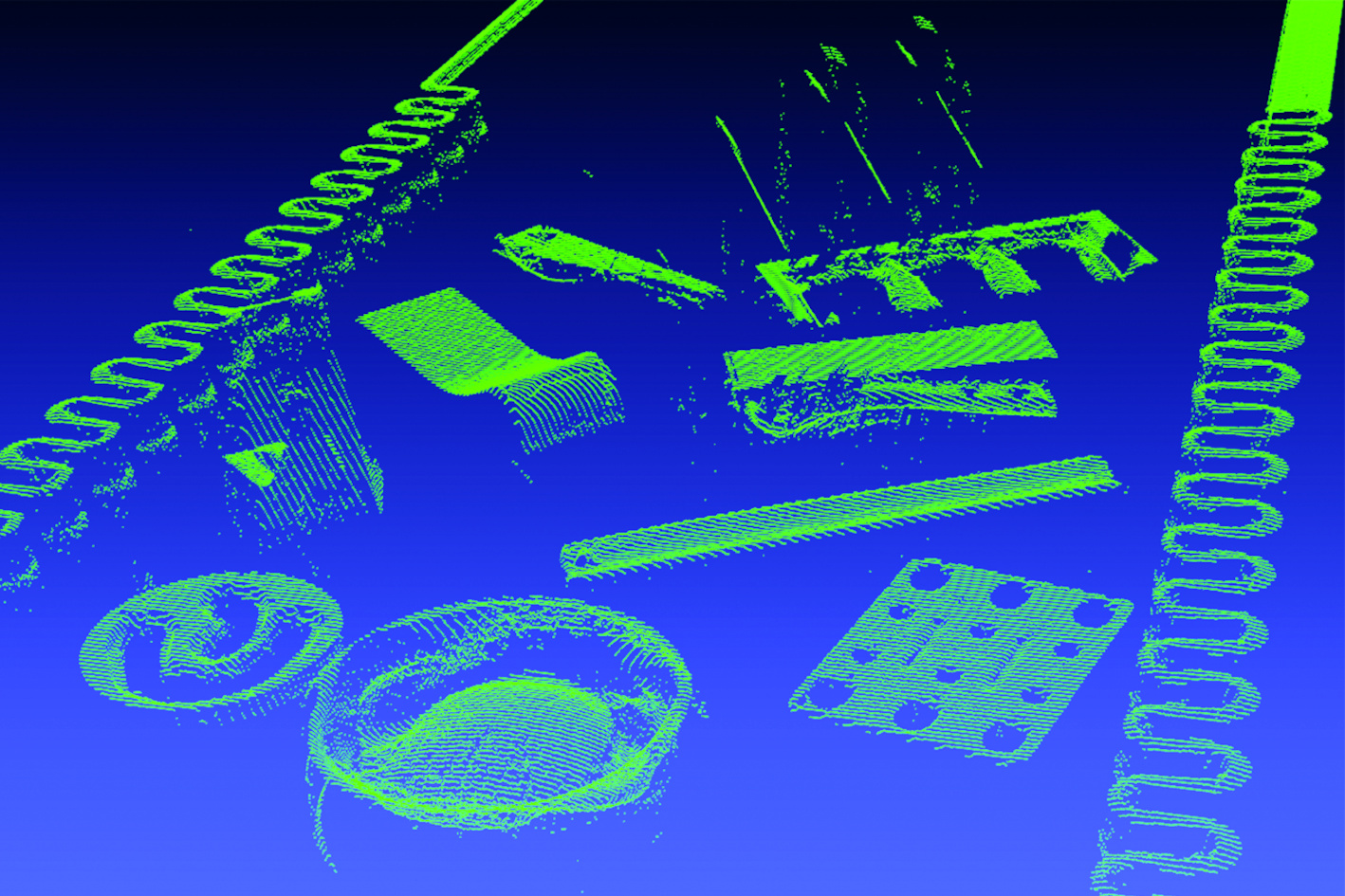

In this context, Fraunhofer ILT is developing absolute measurement interferometric sensors for inline use which make it possible to record geometric features of an object without contacting it. Sensors developed to date have measurement ranges of up to 20 mm, achieve measurement accuracies of less than 1 μm and operate at measurement frequencies of up to 80 kHz; the continuously generated data volume is processed in the measurement cycle to determine distances or thicknesses. FPGA (field-programmable gate arrays) modules are used for uninterrupted processing of large amounts of data. They can be used to parallelize and accelerate computationally intensive operations, and their processing clock is accurate down to nanoseconds.

Initial applications include the autofocusing of laser machining processes and the control of cold rolling processes in metal processing. Fraunhofer ILT has developed robust sensors with up to four independent measuring arms for laser welding or laser material deposition, among others, and which can be individually adapted to applications. Available measuring wavelengths are, for example, in the ranges around 835 nm, 1 μm and 1.5 μm.

The range of services we offer includes feasibility studies for customers’ specific tasks, the development of new processes, components and equipment, and individual consulting.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT