The complexity of fiber laser systems can be reduced enormously with fiber Bragg gratings (FBGs). If the optical gratings are written directly into the fiber, they can replace external resonator mirrors. This eliminates the need for time-consuming mirror alignment. Not only does direct fiber integration reduce system complexity, susceptibility to interference and costs, but the brilliance of the emitted laser radiation also increases significantly.

Concept for fiber integration

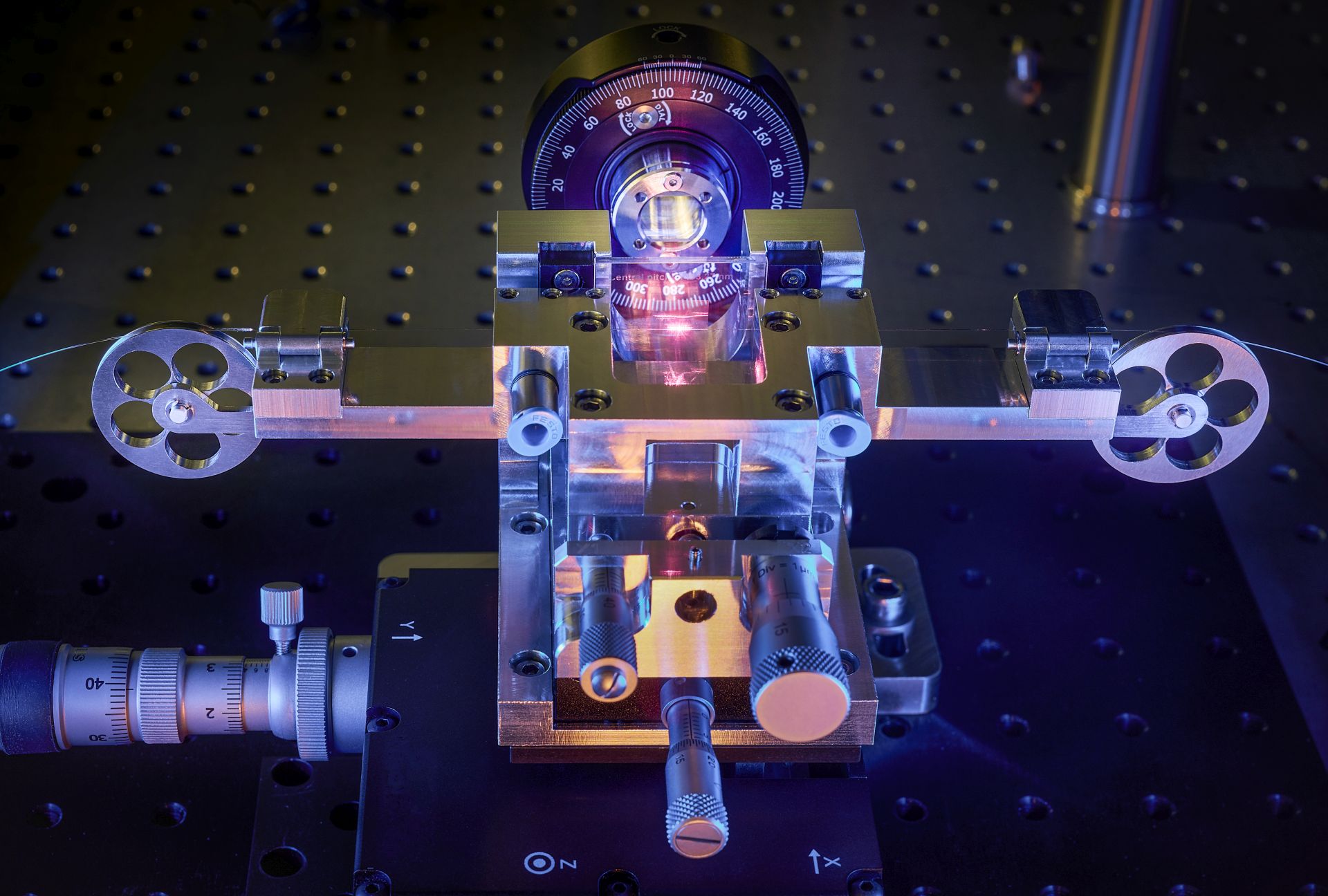

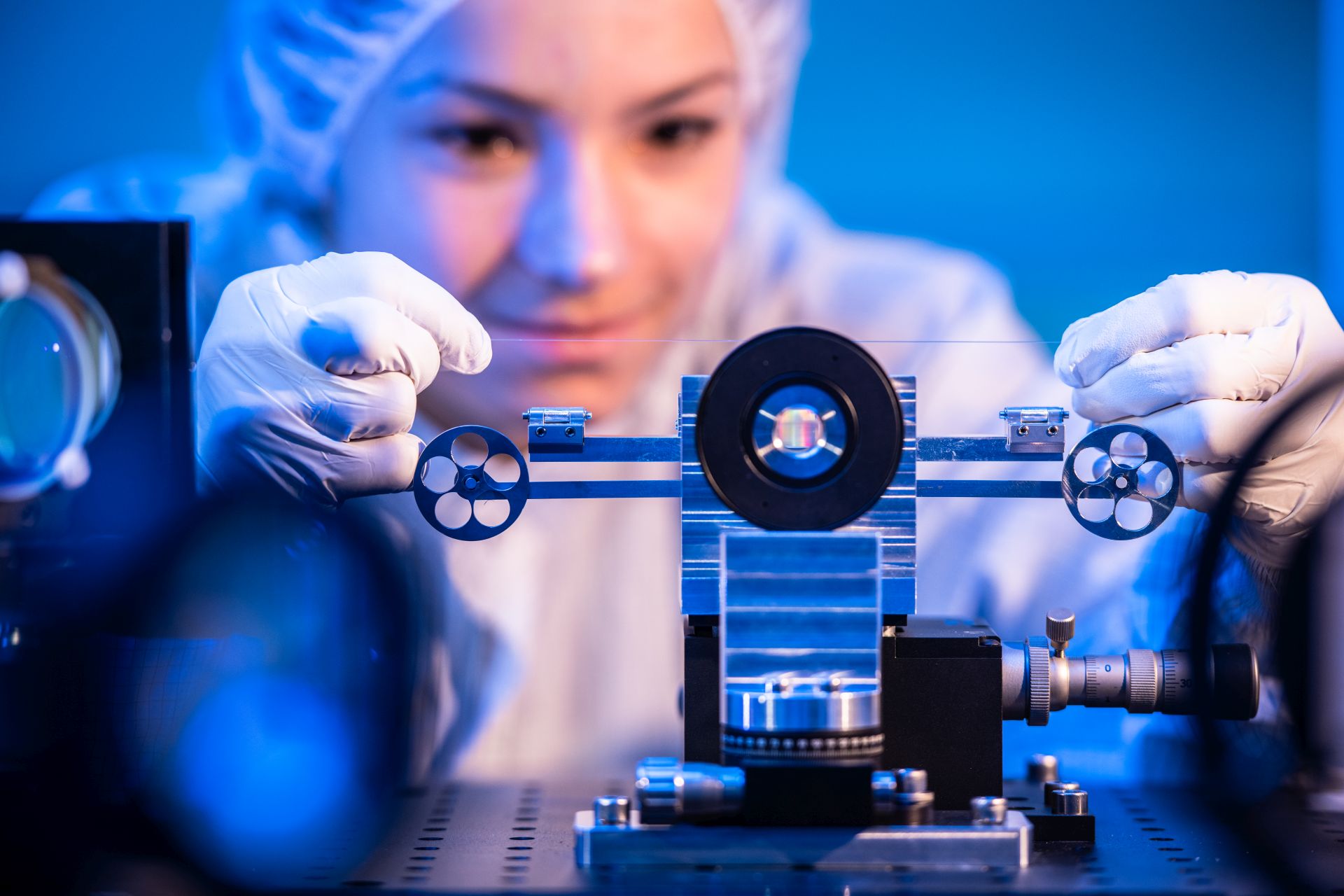

In 2019, within the BMBF-funded EKOLAS project, Fraunhofer ILT took part in developing a process that had already been established for inserting FBGs into the interior of optical fibers, in this case for single-mode fibers with a core diameter of six micrometers. Coordinated by Laserline, the consortium succeeded in writing the fiber Bragg gratings into quartz fibers with a core diameter of 100 micrometers using USP lasers: The material melts briefly under the influence of the ultrashort laser pulses, cools down again very quickly and changes its optical properties in the bulk material processed in this way. The structure introduced is based on an interference pattern of superimposed light waves designed for this purpose.

A single FBG with a diameter of 100 micrometers is sufficient to relocate the previously external resonator mirrors into the fiber and optimize multimode fiber lasers in many respects. As part of her doctoral thesis, the Fraunhofer researcher also transferred this process, which she continued to develop, to fiber-coupled diode lasers. For her innovative research, she was awarded third place in the prestigious Hugo Geiger Prize on February 19, 2025, a prize that is awarded annually by the Free State of Bavaria and the Fraunhofer-Gesellschaft.

Same concept - new objective

In her work, Klein focused not only on multimode fiber lasers, but also on optimizing diode lasers, which are needed to pump solid-state lasers. This changes the objective. In contrast to fiber lasers, the FBGs are used in this application to improve the spectral properties of the diode laser radiation. Some background: In order to raise the energy level of the laser-active medium during optical pumping, the medium is excited with a specific wavelength. Only then can the medium optimally absorb this radiation.

However, diode lasers emit broadband radiation. For this reason, the researcher developed a concept to specifically reduce the bandwidth and stabilize the wavelength of the laser radiation. Once again, a directly inscribed fiber Bragg grating is central to this approach. It ensures that the high-power diode lasers used only emit the desired wavelength. Thanks to this increase in brilliance, the energy input into the solid-state laser is many times more efficient and, therefore, more cost-effective: an enormous advantage for industrial applications in which cost-effectiveness and energy efficiency are playing an increasingly important role!

Complex integration

Klein continued to develop the process as part of an in-house project at the Fraunhofer-Gesellschaft. Here too, as in the EKOLAS project, her aim was to inscribe the optical gratings in multimode fibers used as waveguides for diode lasers. “Normally, laser technology is all about miniaturization. In my research work, it was exactly the opposite,” she explains. She had to transfer the USP process, developed for a core diameter of six micrometers, to a diameter of 100 micrometers. The difficulty lay in the details: It was extremely complicated to seamlessly and precisely align the FBG segments; furthermore, energy management was very challenging. In order to inscribe the many gratings in the much larger multimode fibers in a single step, she would theoretically have had to multiply the energy input. However, this option was ruled out from the very beginning.

Klein mastered the challenge by lining up over a dozen of the FBGs, which are only six micrometers in size, in several exposure processes. It was important to work seamlessly. “The writing process would have been much easier with an angular core geometry,” she reports. Writing the FBG up to the outermost edges was enormously complicated in terms of the required precision. However, there was no alternative to this seamless precision – in terms of maximum reflectivity of the grating – to generate efficient resonator structure of the fiber laser.

When transferring this concept for the frequency stabilization of diode lasers, she focused on designing the FBG properties in such a way that the diode laser only emits a desired wavelength. Klein no longer pursued the goal of maximizing the FBG reflectivity. Instead, she specifically adapted the FBG properties to optimize the spectral properties of the diode laser radiation for pumping applications, for example.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT