Carstens, H., Högner, M., Saule, T., Holzberger, S., Lilienfein, N., Guggenmos, A, Jocher, C., Eidam, T., Esser, D., Tosa, V. , Pervak, V., Limpert, J., Tünnermann, A., Kleineberg, U., Krausz, F., Pupeza, I.:

High-harmonic generation at 250 MHz with photon energies exceeding 100 eV.

Optica 3 Nr. 4, 366-369 (2016)

Grossmann, D., Reininghaus, M., Kalupka, C., Kumkar, M., Poprawe, R.:

Transverse pump-probe microscopy of moving breakdown, filamentation and self-organized absorption in alkali aluminosilicate glass using ultrashort pulse laser

Opt. Expr. 24, (20), 23221-23231 (2016)

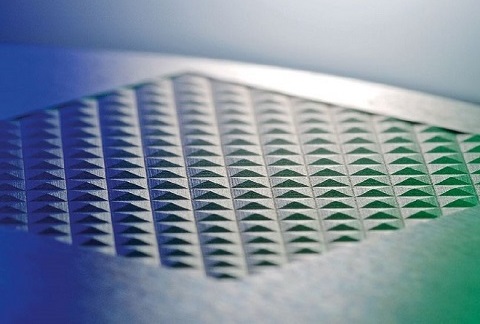

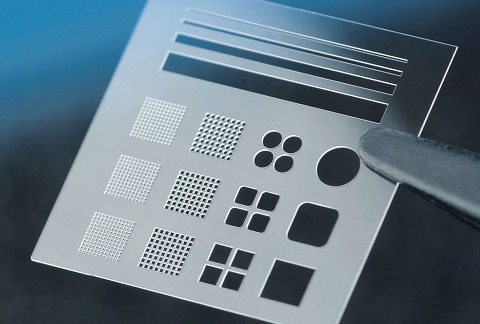

Hambach, N., Hartmann, C., Keller, S., Gillner, A.:

High density perforation of thin Al-Foils with Ultra Short Pulse Lasers in dependence on the repetition rate

J. Laser Micro/Nanoeng, 11 (2), 192-198 (2016)

Kalupka, C., Finger, J., Reininghaus, M.:

Time-resolved investigations of the non-thermal ablation process of graphite induced by femtosecond laser pulses

J. Appl. Phys. 119, 153105 (5 S.) (2016)

Russbueldt, P., Mans, T., Hoffmann, D., Schippel, S.:

High-average power ultrafast Yb: Innoslab amplifier

In: Ultrashort Pulse Laser Technology: Laser Sources and Applications

Eds.: Nolte, S.; Schrempel, F.; Dausinger, F. Cham [u.a.]: Springer (2016), 117-134

Wueppen, J., Strotkamp, M., Hoffmann, D., Russbueldt, P., Mans, T., Fritzler, S., Schippel, S.:

Laser-triggered electron source for x-ray applications

In: Ultrashort Pulse Laser Technology: Laser Sources and Applications

Eds.: Nolte, S.; Schrempel, F.; Dausinger, F. Cham [u.a.]: Springer (2016), 337-349

Finger, J., Kalupka C., Reininghaus, M.:

High power ultra-short pulse laser ablation of IN718 using high repetition rates

J. Materials Processing Technol. 226 (Dec.), 221-227 (2015)

Reininghaus, M., Kalupka, C., Faley, O., Holtum, T., Finger, J., Stampfer, C.:

Dynamics of ultrashort pulsed laser radiation induced non-thermal ablation of graphite

Appl. Phys. A Online First (6 S.) (2014)

Finger, J., Weinand, M., Wortmann, D.:

Ablation and cutting of carbon-fiber reinforced plastics using picosecond pulsed laser radiation with high average power

J. Laser Appl. 25, (4), 042007-1 (5 S.) (2013)

Finger, J., Weinand, M., Wortmann, D.:

Investigations on processing of carbon fiber reinforced plastics using ultrashort pulsed laser radiation with high average power

ICALEO, 32th International Congress on Applications of Lasers & Electro-Optics : October 6-10, 2013, Miama/Fl., USA, Paper 1905 (6 S.) (2013)

Scotti, G., Trusheim, D., Kanninen, P., Naumenko, D., Schulz-Ruhtenberg, M., Snitka, V., Kallio, T., Franssila, S.:

Picosecond laser ablation for silicon micro fuel cell fabrication

J. Micromech. Microeng. 23, 055021 (14. S.), (2013)

Tulea, C., Caron, J., Wahab, H., Gehlich, N., Hoefer, M., Esser, D., Jungbluth, B., Lenenbach, A., Noll, R.:

Highly efficient nonthermal ablation of bone under bulk water with a frequency-doubled Nd:YVO4 picosecond laser

Proc. SPIE 8565, 85656 E-1 (11 S.) (2013)

Bello-Silva, . S., Wehner, M., de Paula Eduardo, C., Lampert, F., Poprawe, R., Hermans, M., Esteves-Oliveira, M.:

Precise ablation of dental hard tissues with ultra-short pulsed lasers

Lasers in Medical Science, 14 S., (2012)

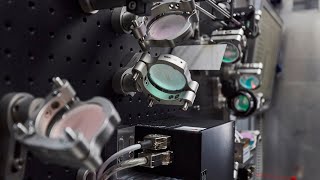

Holzberger, S., Pupeza, I., Esser, D., Weitenberg, J., Carstens, H., Eidam, T., Russbüldt, P., Limpert, J., Udem, T., Tünnermann, A., Hänsch, T., Krausz, F., Fill, E.:

Sub-25 nm High-Harmonic Generation with a 78-MHz Repetition Rate Enhancement Cavity

Proc. CLEO: QELS-Fundamental Science, Optical Society of America, QTh5B.7 (2012)

Hoerstmann-Jungemann, M., Dobrzanski, D., Schaefer, D., Kelbassa, I.:

Functionalization of sapphire surfaces using fs-laser radiation and selective etching

ICALEO. 30. Int. Congr. on Applications of Lasers and Electro-Optics, October 23-27, 2011. M 1203, 1105-1110, (2011)

Reininghaus, M., Finger, J., Faley, O., Wortmann, D., Stampfer, C.:

Non-thermal ablation of graphite by ultrashort pulsed fs-laser radiation

ICALEO. 30. Int. Congr. on Applications of Lasers and Electro-Optics, October 23-27, 2011. N 102, 8 S., (2011)

Schaefer, D., Beckmann, D., Hoerstmann-Jungemann, M., Kelbassa, I.

Waveguides and markings inside transparent materials by fs-laser radiation

ICALEO 30. Int. Congr. on Applications of Lasers and Electro-Optics, October 23-27, 2011. M1004,5 S., (2011)

Trusheim, D., Schulz-Ruhtenberg, M., Smeets, M., Das, J., Wieduwilt, J.:

Influence of ultra-short pulse laser ablation of silicon nitride passivation layers on electronical cell properties

26th European Photovoltaic Solar Energy Conference and Exhibition (EU PVSEC), Hamburg, (2011)

Wortmann, D., Reinighaus, M., Finger, J., Dold, C., Russbueldt, P., Poprawe, R.:

The physics in applications of ultrafast lasers

Proc. SPIE 8306, 830603, 6 S., (2011)

Kelbassa, I., Wortmann, D., Mans, T., Gottmann, J., Russbueldt, P., Weitenberg, J., Brajdic, M., Hermans, M., Beckmann, D., Poprawe, R.:

High-power ultra-short pulse laser radiation: New sources as key enablers for emerging applications

Pacific International Conference on Applications of Lasers and Optics (PICALO), Shangri-La Hotel, Wuhan, China, 6 S., (2010)

D. Esser, D. Mahlmann, D. Wortmann, J. Gottmann:

Interference microscopy of femtosecond laser written waveguides in phosphate glass

Appl. Phys. B - Lasers and Optics 96, Nr 2-3, 5 S., (2009)

I. Mingareev, A. Horn:

Melt dynamics of aluminium irradiated with ultrafast laser radiation at large intensities

J. Appl. Phys. 106, 13513, 7 S., (2009)

D. Wortmann, I. Mingareev, A. Brand, A. Horn:

Micro-welding of glass by fs-laser irradiation and process observation using fs-pump-probe white light interference microscopy

Conference on Lasers and Electro-Optics 2009 and the European Quantum Electronics Conference. CLEO Europe - EQEC 2009, Munich, Mulhouse: European Physical Society, CM2.2 THU, 1 S., (2009)

A. Horn, I. Mingareev, J. Gottmann, A. Werth, U. Brenk:

Dynamical detection of optical phase changes during micro-welding of glass with ultra-short laser radiation

Meas. Sci. Technol 19, 1-6, (2008)

J. Gottmann, D. Wortmann, M. Hörstmann-Jungemann:

Fabrication of sub-wavelength surface ripples and in-volume nanostructures by fs-laser induced selective etching

Appl. Surf. Sci. doi. 10.1016/j.apsusc.2008.10.097 (Online), (2008)

D. Wortmann, J. Gottmann:

Fs-Laser structuring of ridge waveguides

Appl. Phys. A 93, 197-201, (2008)

D. Ganser, L. Starovoytova, D. Wortmann, J. Gottmann, I. Vasilief, L. Moiseev:

Growth of Nd:Gd3Ga5O12 thin films by pulsed laser deposition for planar waveguide laser

J. Laser Micro/Nanoeng. 3, 19-23, (2008)

R. Poprawe, A. Gillner, D. Hoffmann, J. Gottmann, W. Wawers, W. Schulz:

High speed high precision ablation from ms to fs

Proc. SPIE 7005, 12 S., (2008)

A. Horn, I. Mingareev, A. Werth, M. Kachel, U. Brenk:

Investigations on ultrafast welding of glass-glass and glass-silicon

Appl. Phys. A 93, 171-175, (2008)

A. Horn, I. Mingareev, A. Werth, M. Kachel:

Joining of thin glass with semiconductors by ultra-fast high-repetition laser welding

Proc. SPIE 6880, 6 S., (2008)

J. Gottmann, L. Moiseev, I. Vasilief, D. Wortmann:

Manufacturing of Er:ZBLAN ridge waveguides by pulsed laser deposition and ultrafast laser micromachining for green integrated lasers

Mat. Sci. Eng. B 146, 245-251, (2008)

J. Gottmann, D. Wortmann, R. Wagner:

Manufacturing of periodical nanostructures by fs-laser direct writing

Proc. SPIE 7022, 702202-1-702202-10, (2008)

D. Wortmann, J. Gottmann, N. Brandt, H. Horn-Solle:

Micro- and nanostructures inside sapphire by fs-laser irradiation and selective etching

Opt. Expr. 16, Nr 3, 1517-1522, (2008)

A. Horn, I. Mingareev, A. Werth, M. Kachel, U. Brenk:

Non-interferometric transient quantitative phase microscopy for ultrafast engineering

Appl. Phys. A 93, 165-169, (2008)

I. Mingareev, A. Horn:

Time-resolved investigations of plasma and melt efections in metals by pump-probe shadowgraphy

Appl. Phys. A 92, 917-920, (2008)

M. Hörstmann-Jungemann, J. Gottmann ,D. Wortmann:

Time resolved measurement of the dielectric function during direct fs-laser writing of SiO2 and sapphire

Proc. LPM2008 - 9th Int. Symposium on Laser Precision Microfabrication

5 S., (2008)

I. Miyamoto, A. Horn, J. Gottmann, D. Wortmann, F. Yoshino:

Fusion Welding of Glass Using Femtosecond Laser Pulses with High-repetition Rates

J. Laser Micro/Nanoeng. 2, 57-63, (2007)

I. Miyamoto, A. Horn, J. Gottmann:

Local Melting of Glass Material and Its Application to Direct Fusion Welding by Ps-laser Pulses

J. Lasermicro/Nanoeng. 2, 7-14, (2007)

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT