Nguyen,N., Brosda, M., Olowinsky, A., Gillner, A.:

Absorber-free quasi-simultaneous laser welding of transparent microfluidic devices.

LAMP-8th International Congress on Laser Advanced Materials Processing, 21.- 24.5.2019, Hiroshima Japan. Proceedings of LAMP2019, Micro Welding, 19-035 (Th33-L14, A120263), (7 S.), (2019)

Nguyen, N.P., Otto, G.:

Laserdurchstrahlschweißen transparenter Kunststoffe - Teil 3: Technisch-wirtschaftliche Aspekte

JOINING PLASTICS -FUEGEN VON KUNSTSTOFFEN 13 (3-4), 176-181 (2019)

Engelmann, C., Hopmann, C., Wurzbacher, S.

Laserstrahlmikrostrukturierung von Magnesiumblechen aus ME20 – Potenziale für die In-Mould-Assembly von Kunststoff/Magnesium-Hybridverbindungen.

JOINING PLASTICS -FUEGEN VON KUNSTSTOFFEN 13(3-4), 182-189 (2019)

Engelmann, C., Gardiner, G., Voithofer, J., Popow, V., Weidmann, S., Eckstädt, J.:

Inside Manufacturing: Automated joining of hybrid metal-thermoplastic composite structures.

CompositesWorld 10(5), 24-31 (2019)

van der Straeten, K., Sparla, J., Olowinsky, A., Gillner, A.:

Influence of Self-Organizing Microstructures on the Wettability of Molten Plastic on Steel for Hybrid Plastic-Metal-Joints.

Welding in the World, Open Access, 1-11 (2019)

https://doi.org/10.1007/s40194-019-00765-6 (Open Access)

Nguyen, P., Fatherazi, P., Nippgen, S., Brosda, M., Olowinksy, A., Gillner, A.:

Investigations on energy deposition in polycarbonate by picosecond laser pulses for welding applications.

Procedia CIRP 74, 315-319 (2018)

https://doi.org/10.1016/j.procir.2018.08.122

van der Straeten, K., Olowinsky, A., Gillner, A.:

Laser-based plastic-metal-joining with self-organizing microstructures considering different load directions.

Journal of Laser Applications 30(3), 32401- (2018)

van der Straeten, K., Nottrodt, O., Zuric,M., Olowinksy, A., Abels, P., Gillner, A.:

Polygon scanning system for high-power, high-speed microstructuring.

Procedia CIRP 74, 491-494 (2018)

van der Straeten, K., Olowinsky, A., Gillner, A.:

Influence of Climatic Changes on the Joint Strength of Laser Joined Plastic-Metal-Hybrids.

Journal of Laser Micro/Nanoengineering 13(3), 287-291 (2018)

van der Straeten, K., Olowinsky, A., Gillner, A.:

Influence of climatic changes on the joint strength of laser joined plastic-metal-hybrids.

The 19th International Symposium on Laser Precision Microfabrication Edinburgh Conference Centre, Heriot-Watt University, Edinburgh, UK, 25-28 June, 2018. Proceedings of LPM2018, #18-007, (4 S.), (2018)

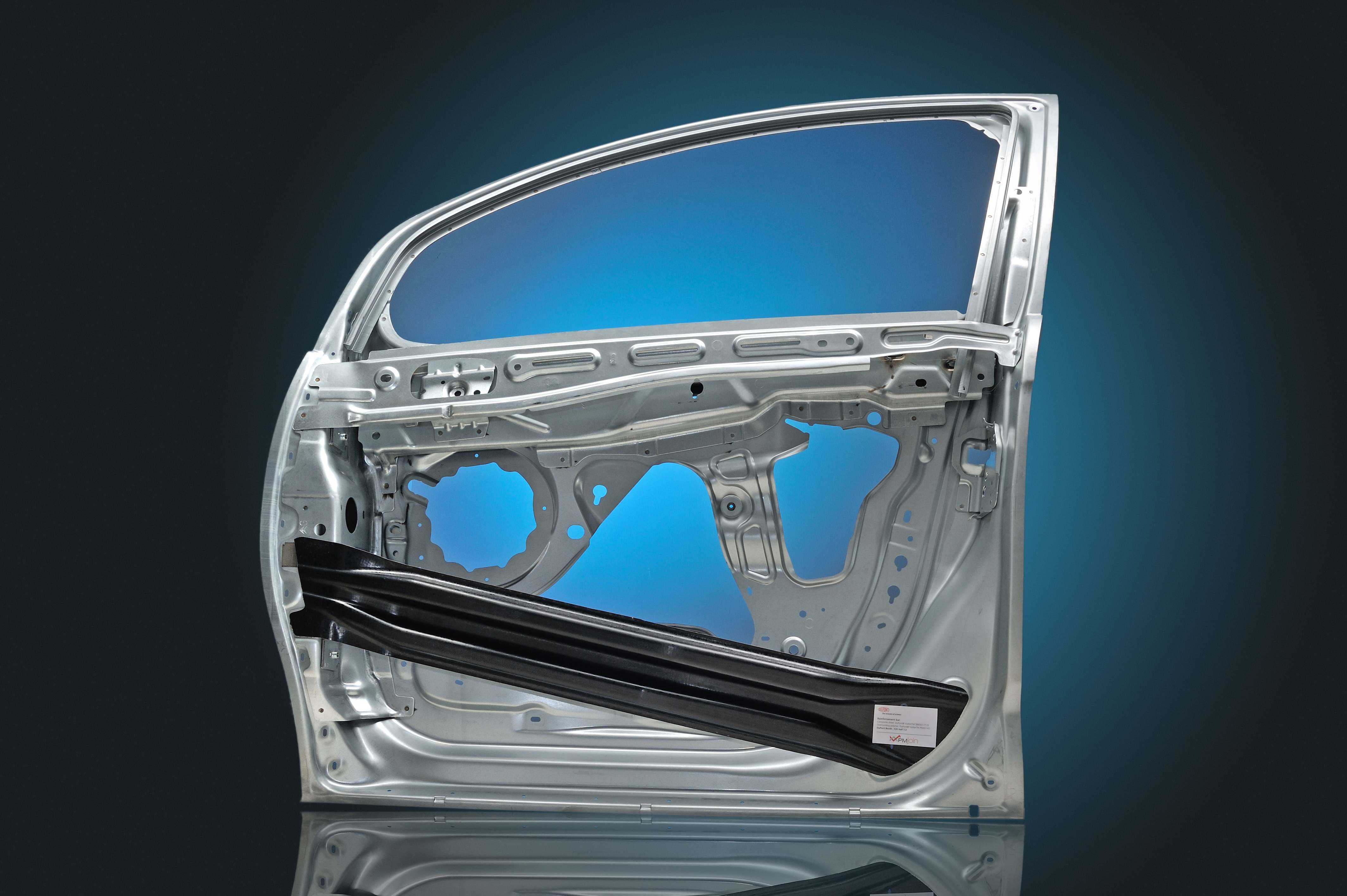

Spancken, D., van der Straeten, K., Beck, J., Stötzner, N.:

Laserstrukturierung von Metalloberflächen für Hybridverbindungen.

Lightweight Design 11(4), 16-23 (2018)

Spancken, D., van der Straeten, K., Beck, J., Stötzner, N.:

Laser Structuring of Metal Surfaces for Hybrid Joints.

Lightweight Design 11(4), 16-21 (2018)

Engelmann, C., Molitor, T.:

Diodenlaser ebnet Weg zu Hybrid-Bauteilen. Reproduzierbares quasisimultanes Laserfügen ersetzt Klebeprozesse.

KUNSTSTOFFE 5, 90-93 (2018)

van der Straeten, K., Engelmann, C., Olowinsky, A., Gillner, A.:

Comparison of laser-based joining approaches for plastic-metal-hybrids - stength vs. process speed.

3. Internationale Konferenz Hybrid Materials and Structures, 18.-19. April 2018 Bremen, Germany. Proceedings Hybrid Materials & Structures 2018, S. 203-208 (2018)

van der Straeten, K. , Wonschik, K.J., Olowinsky, A., A. Gillner, A.:

Self-organizing Microstructures on Aluminum for Joining with Fiber-reinforced Plastics.

IIW 2017 70th International Conference. June, 25-30, Shanghai, P.R. China, E79-E84, 1-6 (2017)

Spancken, D., van der Straeten, K., Beck, J., Hofmann, S., Büter, A.:

Lasertechnik für den Leichtbau - Materialhybride aus Kunststoff und Metall.

8. Landshuter Leichtbau Colloquium. Landshut, 8.3./9.3.2017. Tagungsband LLC 2017, 88-99, (2017)

van der Straeten, K., Olowinsky, A., Gillner, A.:

Laser-based plastic-metal-joining with self-organizing microstructures considering different load directions.

36th Int. Congr. on Applications of Lasers & Electro-Optics, ICALEO, Oct. 22—26, 2017, Atlanta, GA USA. Paper 1502 (6 S.) (2017)

Rodríguez, F., Cotto, I., Dasilva, S., Reym P., Van der Straeten, K.:

Speckle characterization of surface roughness obtained by laser texturing.

Procedia Manufacturing 2017, 519-525 (6 S.) (2017)

Engelmann, C., van der Straeten, K., Heinicke, O.:

Lasertechnik ermöglicht klebstofffreie Hybridverbindungen im Spritzgussprozess

Report Kunststoffland NRW 2017 (1), 8-9 (2017)

Engelmann, C., Oster, L., Olowinsky, A., Gillner, A., Mamuschkin, V., Arntz, D.:

Novel process for butt-joined plastic-metal hybrid compounds

Journal of Laser Applications 29, 22416- (2017)

Brosda, M., Olowinsky, A., Pelzer, A.

Laser Encapsulation of Organic Electronics with Adapted Diode Lasers in Flexible Production Processes

Physics Procedia 83, 214-224 (2016)

LANE 2016, Proceedings of the LANE 2016, Fürth, Germany

van der Straeten, K., Zibner, F., Olowinsky, A., Gillner, A.:

Laser-based joining of hybrid plastic-metal-components by increasing specific adhesion.

35th Int. Congr. on Applications of Lasers & Electro-Optics (ICALEO® 2016) October 17-20, 2016. Online Proc. Paper 807. (6 S.) (2016)

Engelmann, C., Eckstaedt, J., Olowinsky, A., Aden, M., Mamuschkin, V.

Experimental and Simulative Investigations of Laser Assisted Plastic-metal-joints Considering Different Load Directions

Physics Procedia 83, 1118-1129 (2016)

LANE 2016, Proceedings of the LANE 2016, Fürth, Germany

Engelmann, C., Oster, L., Olowinsky, A., Mamuschkin, V., Arntz, D.:

Novel process for Butt-joined plastic-metal hybrid compounds

35th Int. Congr. on Applications of Lasers & Electro-Optics, ICALEO, October 16-20, 2016, San Diego, US. (5 S.) (2016)

Mamuschkin, V., Olowinsky, A., Engelmann, C.,

Improvement of Energy Deposition in Absorber-free Laser Welding through Quasi-simultaneous Irradiation

Physics Procedia 83, 472-482 (2016)

LANE 2016, Proceedings of the LANE 2016, Fürth, Germany

van der Straeten, K., Britten, S., Schneider, F., Janssen, S., Engelmann, C.:

Lasertechnik für industrielle Leichtbauanwendungen

Kunststoffe Nr 5, 34-38 (2016)

van der Straeten, K., Burkhardt, I, Olowinsky, A., Gillner, A.

Laser-induced self-organizing microstructures on steel for joining with polymers

Physics Procedia 83, 1137-1144 (2016) LANE 2016, Proceedings of the LANE 2016, Fürth, Germany

Aden, M., Mamuschkin, V., Olowinsky, A.:

Influence of carbon black and indium tin oxide absorber particles on laser transmission welding

Opt. Laser Technol. 69, 87-91 (2015)

Brosda, M., Mamuschkin, V., Olowinsky, A.:

Laserwelding of transparent polymer films

LIM 2015 Lasers in Manufacturing, Munich, June 22-25, (5. S.) (2015)

Cosson, B., Deléglise, M., Knapp, W.:

Numerical analysis of thermoplastic composites laser welding using ray tracing method

Composites Part B 68, 85-91 (2015)

Engelmann, C., Eckstädt, J., Olowinsky, A., Aden, M., Mamuschkin, V.:

Examination of the bond strength of laser assisted plastic-metal-joints considering different load directions

LAMP 2015 – the 7th International Congress on Laser Advanced Materials Processing, Kitakyushu, Fukuoka, Japan, (6 S.) (2015)

Engelmann, C., van der Straeten, K., Mamuschkin, V., Olowinsky, A.:

Laserbasierte Fügeverfahren für faserverstärkte Kunststoffe

Große Schweißtechnische Tagung, DVS Congress, Nürnberg 14.-17. September 2015. (5 S.) (2015)

Mamuschkin, V., Engelmann, C., Aden, M., Olowinsky, A.:

Comparison of different irradiation methods in absorber-free laser transmission welding

LAMP 2015 – the 7th International Congress on Laser Advanced Materials Processing. Kitakyushu, Fukuoka, Japan, May 26-29, 2015. (6 S.) (2015)

Mamuschkin, V., Olowinsky, A., van der Straeten, K., Engelmann, C.:

Laser transmission welding of absorber-free thermoplastics using dynamic beam superposition

Proc. SPIE 9356, 93560Y (8 S.) (2015)

van der Straeten, K., Engelmann, C., Olowinsky, A., Gillner, A.:

Laser transmission welding of long glass fiber reinforced thermoplastics

Proc. SPIE 9356, 93560H (7 S.) (2015)

van der Straeten, K., Engelmann, C.:

Laserbasierte Fügeverfahren

Lightweight Design 2, 10-15 (2015)

Hopmann, C., Böttcher, A., van der Straeten, K., Riedel, R., Schneider, F., Engelmann, C., Fischer, K.:

Neue Prozesskette für faserverstärkte Thermoplaste

WT Werkstattstechnik Online 104 (9), 575-580 (2014)

Jänchen, R., Brosda, M., Wendt, G., Olowinsky, A.:

Mit Licht - flexibel und dicht

Pack Report, 46-49 (2014)

Mamuschkin, V., Olowinsky, A., Britten, S., Engelmann, C.:

Investigations on laser transmission welding of absorber-free thermoplastics

Proc. SPIE 8968, (9 S.) (2014)

Aden, M., Mamuschkin, V., Olowinsky, A., Glaser, S.:

Influence of Titanium dioxide pigments on the optical properties of polycarbonate and polypropylene for diode laser wavelengths

J. Appl. Polymer Sci. (early view) (5 S.) (2013)

Aden, M., Liviany, F., Olowinsky, A.:

Joint strength for laser transmission welding of thermoplastics: A simulation approach

International Polymer Processing 28, 79-83 (2013)

Rösner, A.:

Der Laser verbindet Kunststoffe mit metallischen Bauteilen

MM Maschinenmarkt Nr. 18, 36-38 (2013)

Rösner, A., Olowinsky, A.:

Laser welding of polymers

Ind. Laser Sol. 28 (1), 29-31 (2013)

Binetruy, C., Clement, S., Deleglise, M., Franz, C., Knapp, W., Oumarou, M., Renard, J., Roesner, A.:

Glue-free assembly of glass fiber reinforced thermoplastics using laser light.

Proc. SPIE 8065, 80650U, (7 S.) (2011)

Roesner, A., Scheik, S., Olowinsky, A., Gillner, A., Poprawe, R., Schleser, M., Reisgen, U.:

Innovative approach of joining hybrid components.

J. Laser Appl. 23, Nr. 3, 32007, (6 S.), (2011)

Roesner, A., Scheik, S., Olowinsky, A., Gillner, A., Reisgen, U., Schleser, M.:

Laser assisted joining of plastic metal hybrids.

Phys. Proced. 12, 373-380, (2011)

Aden, M., Roesner, A., Olowinsky, A.:

Optical characterization of polycarbonate: Influence of additives on optical properties

J. Polymer Science. Part B: Polymer Physics 48, Nr 4, 451-455 (2010)

Boglea, A., Olowinsky, A., Gillner, A.:

Extending the limits of laser polymer welding using advanced irradiation strategies.

J. Laser Micro/Nanoeng. 5, 138-144, (2010)

Holtkamp, J., Roesner, A., Gillner, A.:

Advances in hybrid laser joining

Int. J. Adv. Manuf. Technol. 47, 923-930, (2010)

Georgiev, G. L., Sultana, T., Baird, R. J., Auner, G., Newaz, G., Patwa, R., Herfurth, H.:

Laser bonding and characterization of Kapton(A (R)) FNTi and Teflon(A (R)) FEPTi systems

J. Mat. Sci 44, 882-888, (2009)

Roesner, A., Abels, P., Olowinsky, A., Matsuo, N., Hino, A.:

Absorber-free laser beam welding of transparent thermoplastics

Proc. of the 27th Int. Conf. on Applications of Lasers and Electro-Optics 2008, ICALEO, Temecula, CA, October 20-23 Paper M303, (7 S.) (2008)

Sari, F., Hoffmann, W.-M., Haberstroh, E., Poprawe, R.:

Applications of laser transmission processes for the joining of plastics, silicon and glass micro parts

Microsystems Technol. 14, 1879-1886, (2008)

Bobzin, K., Theiß, S., Poprawe, R., Roesner, A., Haberstroh, E., Flock, D., Reisgen, U., Wagner, N.:

Der Exzellenzcluster "Integrative Produktionstechnik für Hochlohnländer" der RWTH Aachen University - Herstellung hybrider Metall-Kunststoffbauteile durch moderne Fügeverfahren

Joining Plastics – Fügen von Kunststoffen 2, 210-216, (2008)

Roesner, A., Boglea, A., Olowinsky, A.:

Laserdurchstrahlschweissen von Thermoplasten

Laser Technik J. 5 (4), 28-32, 2008

Abels, P., Roesner, A., Kaierle, S., Mann, S., Olowinsky, A., Matsuo, N., Hino, A.:

Various process monitoring approaches of transparent thermoplastics laser beam welding

Proc. of the 27th Int. Congress on Applications of Lasers & Electro-Optics 2008, ICALEO, Temecula, CA, USA, October 20-23, 2008, 99-104, (2008)

Franz, C., Mann, S., Kaierle, S.:

Comparison of process monitoring strategies for laser transmission welding of plastics

Proc. of ICALEO 2007, Orlando, Fl. 602-606, (2007)

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT