Dahmen, M.:

Laserbasierte Funktionalisierung von partikulären Polyetheretherketon-Beschichtungen auf Aluminiumsubstraten mittels Zwei-Strahl-Ansatz.

Dissertation RWTH Aachen University, 2023, Apprimus Verlag, Aachen, (2023)

http://doi.org/10.18154/RWTH-2023-11484 (Open Access)

Mertin, J.:

Laserbasierte Herstellung von Kupferschichten auf Aluminium-Oxid-Keramiken für Anwendungen in der Leistungselektronik.

Dissertation, RWTH Aachen University, 2023, Shaker Verlag, Düren, (2023)

http://doi.org/10.18154/RWTH-2023-09878 (Open Access)

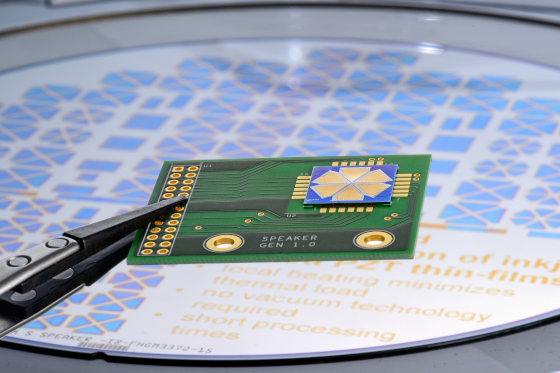

Fink, S., Demir, D., Börner, M., Göken, V., Vedder, C.:

High-Speed Laser Drying of Lithium-Ion Battery Anodes: Challenges and Opportunities.

World Electric Vehicle Journal 14(9), 255- (2023)

https://doi.org/10.3390/wevj14090255 (Open Access)

Frühling, J, Schreyer, S., Fink, S, Vedder, C.:

Laser-based crystallization of oxide ceramic thin films for Solid Oxide Fuel Cells.

WLT/LiM Lasers in Manufacturing Conference 2023. 26. – 29. Juni 2023, München Germany.

Proceedings of World of Photonics, (5 S.), (2023)

Fink, S., Dahmen L., Vedder, C., Stollenwerk, J.:

Laser-based, direct formation of thin copper-nickel alloy films with low thermal coefficient of resistivity.

JOURNAL OF APPLIED PHYSICS 132(20), 205301- (2022)

https://doi.org/10.1063/5.0124000 (Open Access)

Scheld, W., Lobe, S., Uhlenbruck, S., Dellen, C., Sohn, Y., Hoff, L., Vondahlen, F., Guillon, O., Fattakhova-Rohlfing, D.:

Rapid thermal sintering of screen-printed LiCoO2 films.

THIN SOLID FILMS 749, 139177- (2022)

http://dx.doi.org/10.1016/j.tsf.2022.139177

Fink, S., Lübben, J., Schneller, T., Vedder, C., Böttger, U.:

Impact of the processing temperature on the laser-based crystallization of chemical solution deposited lead zirconate titanate thin films on short timescales.

JOURNAL OF APPLIED PHYSICS 131(12), 125302- (9 S.) (2022)

https://doi.org/10.1016/10.1063/5.0084953 (Open Access)

Dahmen, M., Vedder, C., Baek, S., Stollenwerk, J.:

Dual-beam Laser-based Processing of Tribological Polymer Coatings.

12th CIRP Conference on Photonic Technologies [LANE 2022], 4-8 September 2022, Fürth, Germany - (2022)

Hoff, L.C., Scheld, W.S., Vedder, C., Stollenwerk, J.:

Laser sintering of ceramic-based solid-state battery materials.

SPIE Photonics West 2022 On Demand - (2022)

https://doi.org/10.1117/12.2607752

Hoff, L.C., Scheld, W.S., Vedder, C., Stollenwerk, J., Lobe, S., Uhlenbruck, S.:

Laser sintering of ceramic-based solid-state battery materials.

WLT/Lasers in Manufacturing Conference 2021, International Congress Center, Munich, Germany. Proceedings of World of Photonics, (7 S.), (2021)

Fuchs, F., Vedder, V., Stollenwerk, J., Loosen, P.:

Determination of the temperature dependent optical properties of amorphous silicon thin films at elevated temperatures.

OPTICS EXPRESS 29, 41356-41362 (2021)

https://doi.org/10.1364/OE.437507

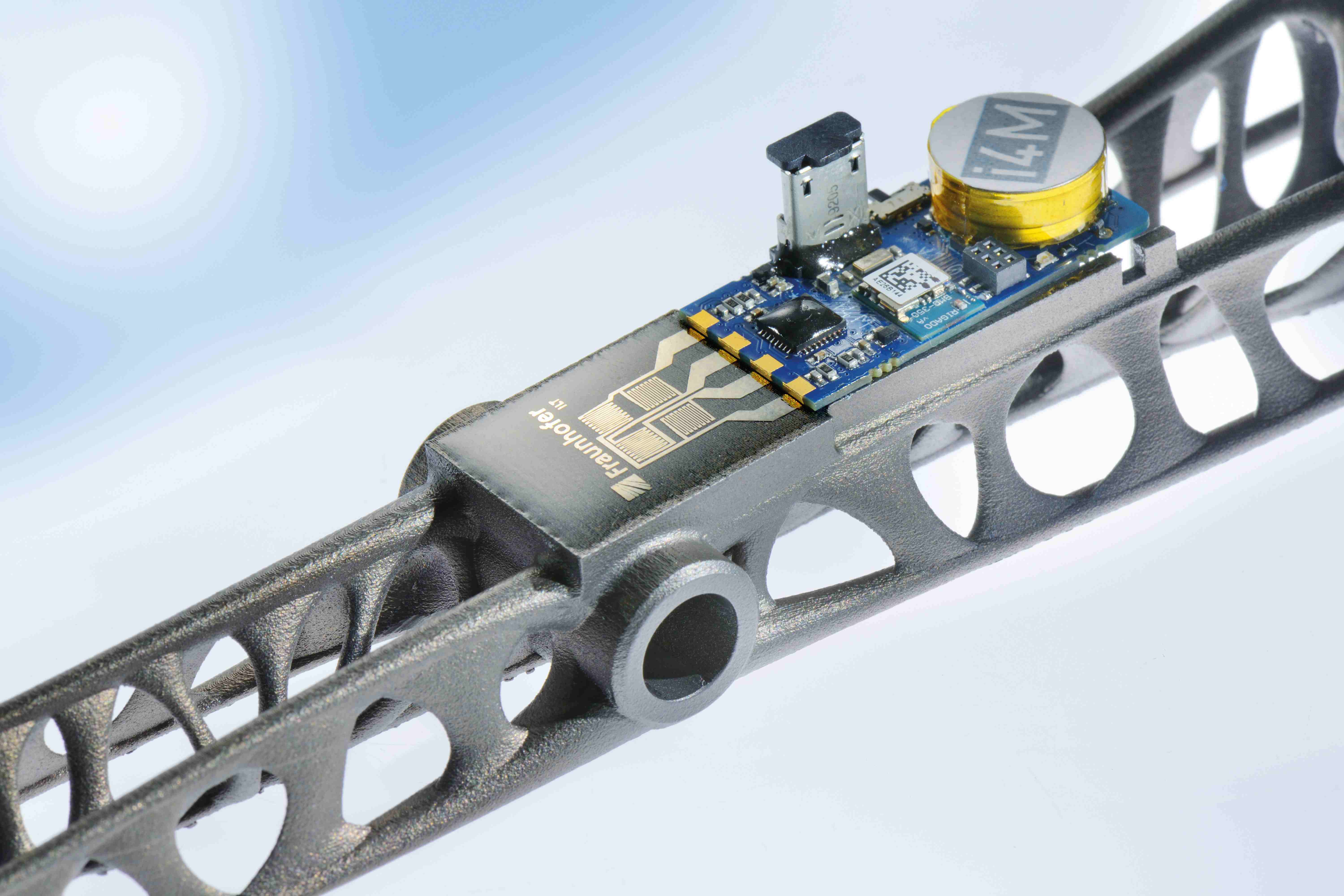

Rehberger, M., Noll, M.:

DMS-Sensoren aus dem 3D-Druck mit Low-Power-Funk-Telemetrie.

Elektronik-Praxis 17, 46-48 (2020)

Rehberger, M., Vedder, C., Schleifenbaum, J.H.:

Challenges and Opportunities for Laser-based Additive Manufacturing of Strain Sensors.

WLT/LiM Lasers in Manufacturing Conference 2019 Munich, June 24 - 27, 2019. Proceedings of World of Photonics, (8 S.) (2019)

Völl, A., Wollgarten, S., Stollenwerk, J., Loosen, P.:

Application specific intensity distributions for laser functionalization of (nano-)ceramic coatings as wear protection.

WLT/LiM Lasers in Manufacturing Conference 2017. Munich, June 26-29 2017. Proceedings of World of Photonics, (8 S.), (2017)

Sändker, H., Stollenwerk, J., Loosen, P.:

Laser-based process for polymeric tribological coatings on lightweight components.

SURFACE & COATINGS TECHNOLOGY 332, 391-398 (2017)

http://dx.doi.org/10.1016/j.surfcoat.2017.06.075

Opitz, M., Go, D., Lott, P., Müller,S., Stollenwerk, J., Kuehne, A., Roling, B.:

On the interplay of morphology and electronic conductivity of rotationally

spun carbon fiber mats.

JOURNAL OF APPLIED PHYSICS 122, 105104- (2017)

http://dx.doi.org/10.1063/1.5001509

Sändker, H., Stollenwerk, J., Loosen, P.:

Laser-based Process for Polymeric Coatings on Temperature-Sensitive Metallic Components.

WLT/LiM Lasers in Manufacturing Conference 2017. Munich, June 26-29 2017. Proceedings of World of Photonics, (6 S.) 1-6 (2017)

Bilandžić, M. , Wollgarten, S. , Stollenwerk, J. , Poprawe, R. , Esteves-Oliveira, M. , Fischer, H.:

Glass-ceramic coating material for the CO2 laser based sintering of thin films as caries and erosion protection.

DENTAL MATERIALS 33, 995-1003 (2017)

http://dx.doi.org/10.1016/j.dental.2017.06.008

Buling, A., Sändker, H., Stollenwerk, J., Krupp, U., Hamann-Steinmeier, A.:

Laser Surface Pretreatment of 100Cr6 Bearing Steel - Hardening Effects and White Etching Zones.

APPLIED SURFACE SCIENCE 378, 564-571 (2016)

https://doi.org/10.1016/j.apsusc.2016.03.088

Sändker, H., Stollenwerk, J., Hofmann, J., Loosen, P.:

Laser beam propagation and energy deposition in particulate PEEK layers.

Proceedings of World of Photonics. WLT/ LiM Lasers in Manufacturing, München, 22.06.-25.06.2015 1-9 (2015)

Lott, P., Stollenwerk, J., Wissenbach, K.:

Laser-based production of carbon fibers.

Proceedings 33rd ICALEO International Congress on Applications of Lasers & Electro–Optics, October 19-23, 2014, San Diego, CA, USA. Paper M 602, (6 S.) (2014)

https://doi.org/10.2351/1.4906476

Chen, X., Yagi, M., Akiyama, Y., Machida, O., Ohta, E., Meixner, M.: Stollenwerk, J., Boettger, U., Schneller, T.:

Fabrication of multilayer Pb(Zr0.53Ti0.47)O3 film crystallized by laser annealing.

Japanese Journal of Applied Physics 52 (4), (S.9) (2013)

https://doi.org/10.7567/JJAP.52.09KA06

Hartmann, C., Hambach, N., Jüngst, M., Keller, S., Holtkamp, J., Gillner, A.:

High density perforation of thin Al-foils with ultra short pulse lasers

Proc. of LAMP2013 - the 6th Int. Congr. on Laser Advanced Materials Processing (4 S.) (2013)

Journal of Lasers Micro/NanoEngineering 8(3), 266-270, (2013)

https://doi.org/10.2961/jlmn.2013.03.0013

Hawelka, D., Stollenwerk, J., Pirch, N., Wissenbach, K., Loosen, P.:

Improving surface properties by laser-based drying, gelation, and densification of printed sol-gel coatings.

Journal of Coatings Technology and Research 10, (8 S.) (2013)

https://doi.org/10.1007/s11998-013-9516-0

Stollenwerk, J.:

Energie- und ressourceneffiziente Funktionalisierung temperaturempfindlicher Substrate

Laser Mag. 2013, 8-9 (2013)

Hawelka, D., Stollenwerk, J., Pirch, N., Wissenbach, K.:

Improving Surface Properties by Laser-based Drying, Gelation and Densification of Printed Sol-Gel Coatings

Proc. 16th International Coating Science and Technology Symposium, September 9-12 2012, Midtown Atlanta, GA, 187-190 (2012)

Meixner, M., Stollenwerk, J., Wissenbach, K.:

Production of silver conductive paths by laser processing.

ICALEO: 31. Int. Congress on Applications of Lasers and Electro- Optics, September 23-27, 2012. International Congress on Applications of Lasers & Electro–Optics, Anaheim, CA, USA, (5 S.) (2012)

https://doi.org/10.2351/1.5062476

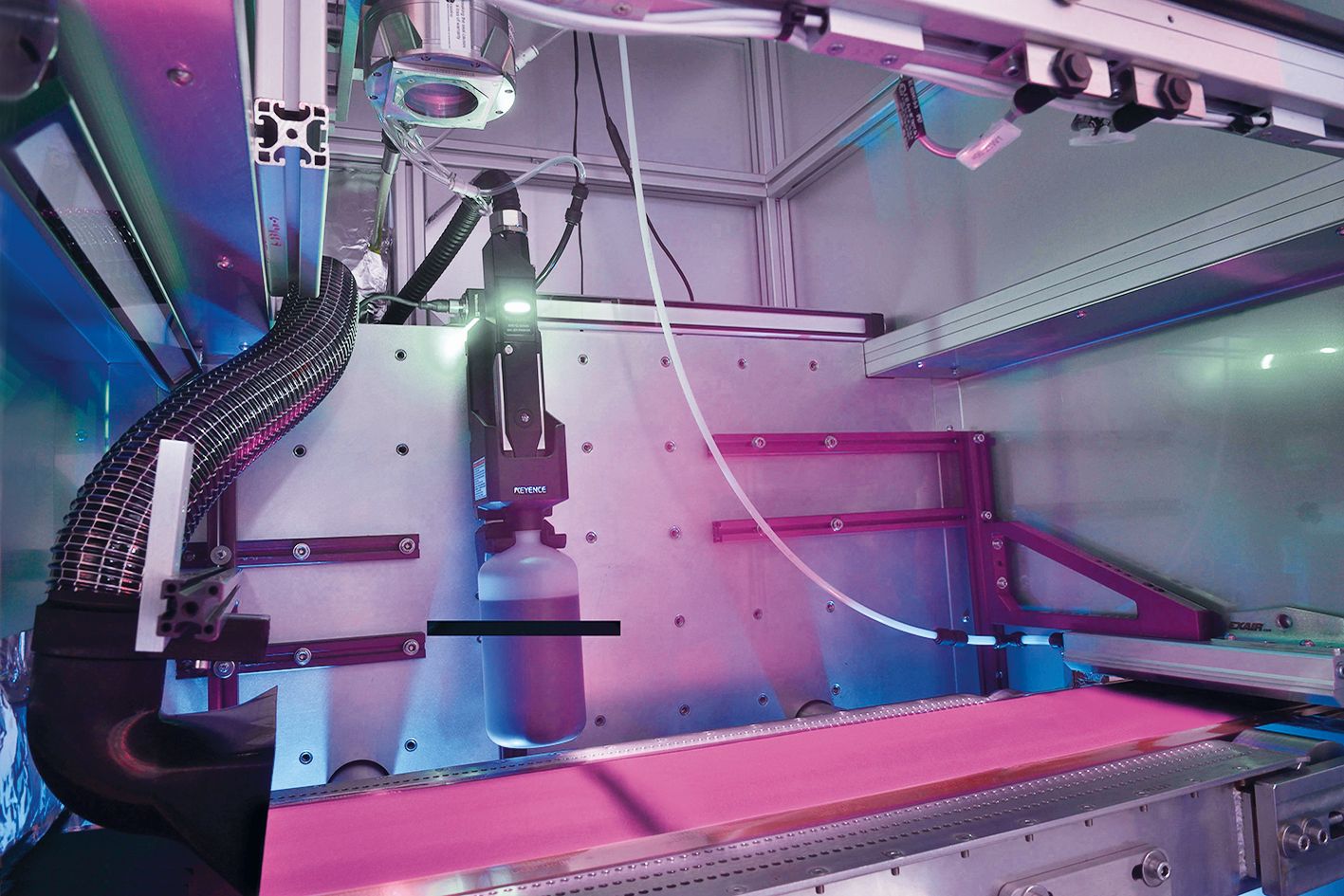

Vedder, C., Stollenwerk, J., Wissenbach, K.:

Process monitoring and control for laser-based thin film treatment.

ICALEO: 31. Int. Congress on Applications of Lasers and Electro- Optics, September 23-27, 2012. International Congress on Applications of Lasers & Electro–Optics, Anaheim, CA, USA, (7 S.) (2012)

https://doi.org/10.2351/1.5062444

Hawelka, D., Stollenwerk, J., Pirch, N., Büsing, L., Wissenbach, K.:

Laser based inline production of wear protection coating on temperature sensitive substrates.

Physics Procedia 12, 490-498 (2011)

https://doi.org/10.1016/j.phpro.2011.03.060 (Open Access)

Vedder, C., Stollenwerk, J., Pirch, N., Wissenbach, K.:

Laser-based manufacturing of metallic conducting paths.

ICALEO 30. Int. Congr. on Applications of Lasers and Electro-Optics, October 23-27, 2011. M804, (5 S.) (2011)

Vedder, C., Stollenwerk, J., Wissenbach, K., Pirch, N.:

Laser-based production of metallic conducting paths.

Phys. Proced. 12, 252-260, (2011)

https://doi.org/10.1016/j.phpro.2011.03.131

Ganser, D., Gottmann, J., Mackens, U., Weichmann, U.:

Pulsed laser deposition of fluoride glass thin films

Appl. Surface Sci. 257, 954-959, (2010)

https://doi.org/10.1016/j.apsusc.2010.07.100

Gasser, A., Meiners, W., Weisheit, A., Willenborg, E., Stollenwerk, J., Wissenbach, K.:

Maßgeschneiderte Oberflächen und Bauteile. Teil 1.

Laser Technik Journal 7 (4), 47-53 (2010)

https://doi.org/10.1002/latj.201090061

Gasser, A., Meiners, W., Weisheit, A., Willenborg, E., Stollenwerk, J., Wissenbach, K.:

Maßgeschneiderte Oberflächen und Bauteile. Teil 2.

Laser Technik Journal 7(6), 22-26 (2010)

https://doi.org/10.1002/latj.201090087

Hawelka, D., Stollenwerk, J., Pirch, N., Wissenbach, K.:

Laser based production of thin wear protection films

ICALEO 2010. 29th International Congress on Applications of Lasers & Electro Optics, Anaheim/Ca., September 26-30, 2010. Paper 1709 (6 S.) (2010)

https://doi.org/10.2351/1.5062088

Trusheim, D., Schulz-Ruhtenberg, M., Hernandez, J. L., Uruena, A., Krantz, S., Morilla, C., Sarnet, T., Olowinsky, A.:

Damage-less laser ablation of thin films for silicon solar cells

Proc. of the 5th Int. WLT-Conf. on Lasers in Manufacturing 2009, Munich, June 15-18, 2009. Ed. by A. Ostendorf [u.a.], Stuttgart: AT Fachverl. (5 S.) (2009)

Vedder, C., Stollenwerk, J., Pirch, N., Wissenbach, K.:

Production technology for transparent and conducting nano layers

Proc. of the 27th Int. Conf. on Applications of Lasers and Electro-Optics 2008, ICALEO, Temecula/CA. October 20th-23rd, Paper N303, (5 S.) (2008)

https://doi.org/10.2351/1.5061416

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT