Current challenges in automotive technology and mobility

The main challenges include the development of environmentally friendly drive systems for vehicles, ships and trains as well as the digitalization of mobility. These encompass intelligent transportation systems that enable autonomous driving, for example. What also plays a crucial role in these developments: digitalization and data processing, lightweight construction and material innovations as well as the further development of battery technology. The framework for action is defined by ensuring that procuring raw materials is sustainable, taking global supply chains into account and following stricter regulatory requirements. Solutions require an approach that integrates all of these and where industry, science, society and economic policy cooperate closely.

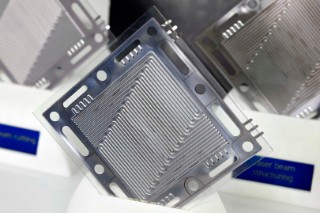

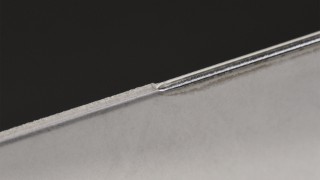

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT