Current challenges in medical technology / health

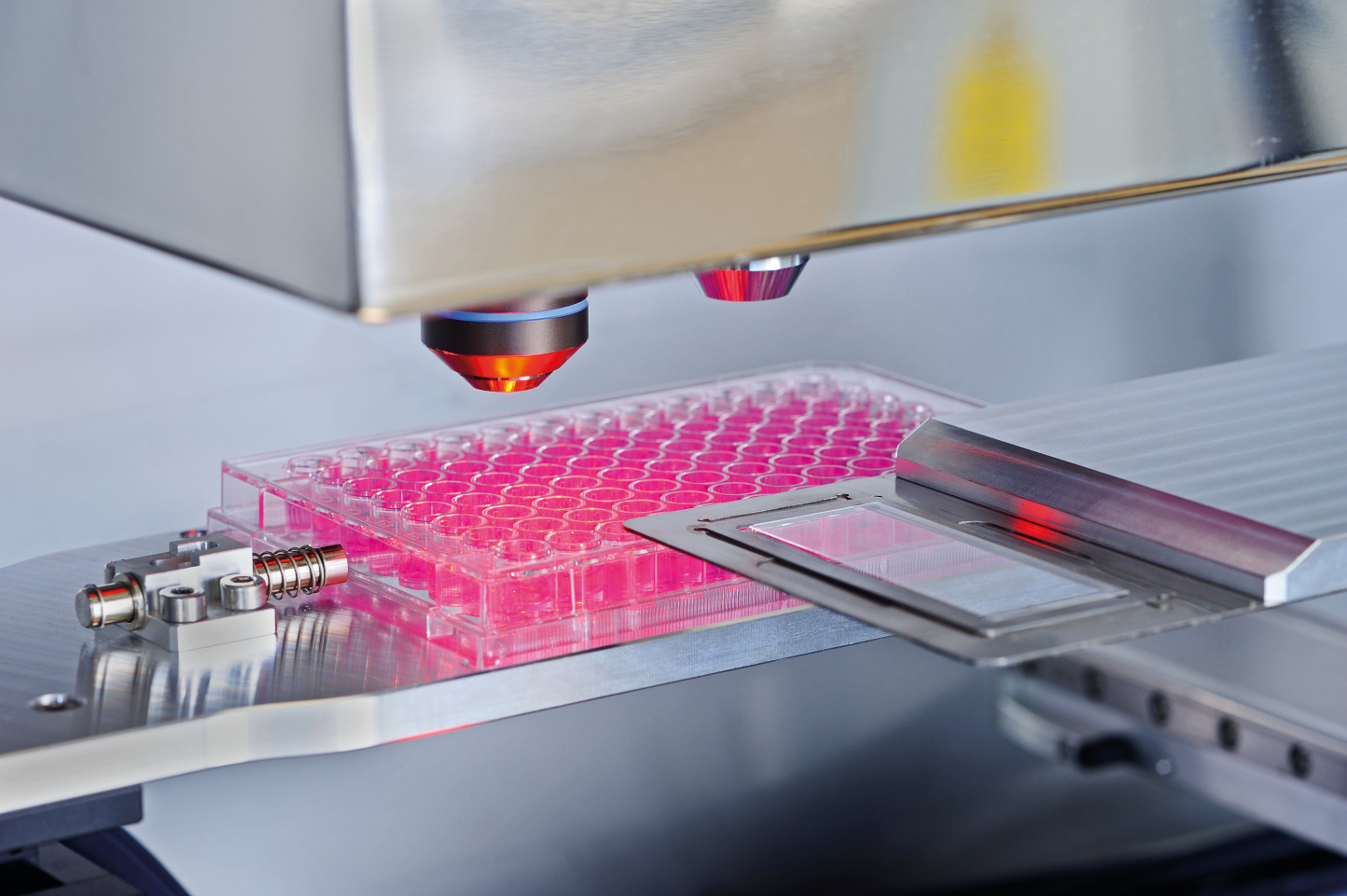

Demographic change poses particular challenges for the healthcare industry. In ageing societies, the need for medical care is growing. However, there is a shortage of specialists and a lack of financial resources in systems financed by contributions. This dilemma can be solved by technological progress, and laser technology is an important driver here. It enables more accurate diagnoses, more efficient laboratory processes, more effective drugs and therapies, gentler surgical procedures, individualized implants and highly effective personalized medicine. What's more, laser-based inline analytics holds great potential for a key cornerstone of healthcare: environmental protectio

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT