Our range of services

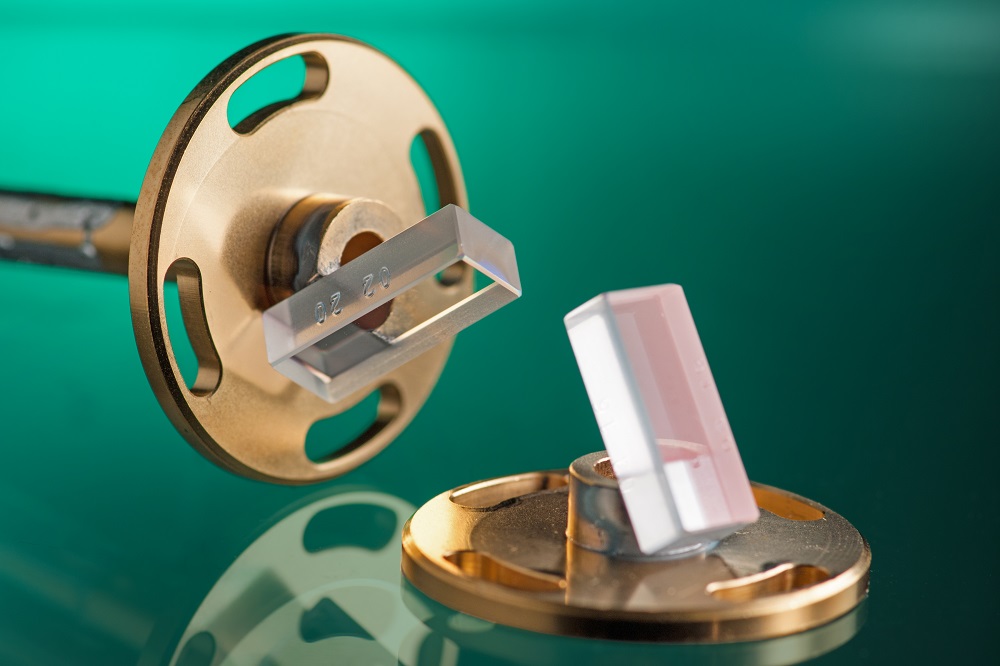

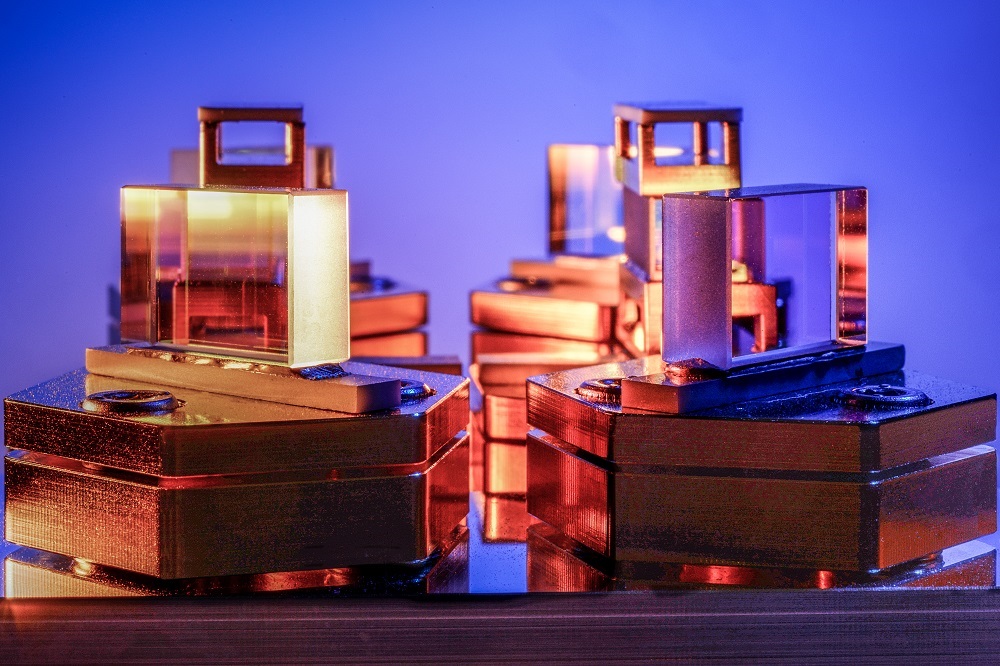

Optomechanically and thermo-mechanically stable laser systems are required wherever classic construction technology reaches its limits. Many applications need such particularly robust systems, which must function reliably under extreme environmental conditions, for example. Mounting processes based on soldering technology for optical and optomechanical components allow the construction of systems suitable for aerospace applications. With its »Future Laser System« (FULAS), Fraunhofer ILT has developed a corresponding technology platform for future satellite-based LIDAR systems. On the basis of this platform, laser systems that detect trace gases in the atmosphere can be designed and constructed specific to a required task. In addition to space applications, the soldering technology can also be used advantageously for classical industrial and research applications, where – in addition to the stability – a low outgassing rate, a favorable aging behavior or good heat conduction of the mounting interface are required. The assembly technology is based on the flexible Pick & Align process developed at Fraunhofer ILT, in which all essential adjustment steps are performed with manually guided robots. In addition to new concepts, the simplification of already existing soldering processes and packages will be promoted.

The range of services encompasses feasibility studies, the development of assembly processes or functional assemblies and their qualification as well as consultancy in the conceptual design of processes and plants.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT