Current challenges in the aerospace industry

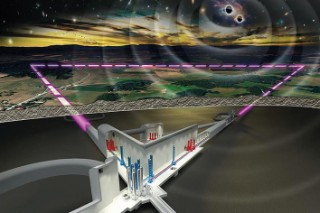

The aviation industry is rising to the challenge of reducing its environmental impact. Companies are looking for more environmentally friendly propulsion systems, sustainable fuels and energy-efficient technologies. In turbine construction, suppliers are developing lighter and more efficient components with new technologies. OEMs, suppliers and research institutes are currently systematically analyzing the potential of hydrogen technologies. In satellite technology, great demands are being placed on laser-based measuring systems, which are used in areas such as communications technology, environmental technology and meteorology.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT