Our Service

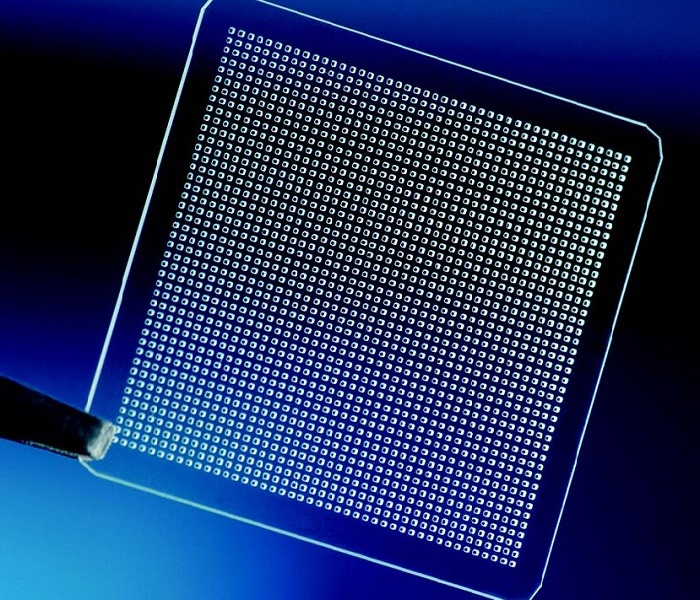

Using ultrashort pulsed laser radiation, transparent materials such as glasses, crystals or ceramics can be ablated, cut, drilled or structured with high precision for a variety of applications. By selectively ablating glass surfaces, for example, markings or scattering centers can be generated for the decoupling of light. Furthermore, material modifications and high-precision structures can be selectively introduced into the volume of transparent materials. Selective laser-induced etching (SLE) offers the possibility of producing any 3D structures and complex components from glass or other materials. In this way, even hollow bodies with complex geometries can be produced in the volume of sapphire, for example, which cannot be produced using conventional methods. This enables the production of complex microfluidics for medical technology, for example. The SLE process is also suitable as a high-precision manufacturing technology for photonic-integrated chips and applications in the field of quantum technologies.

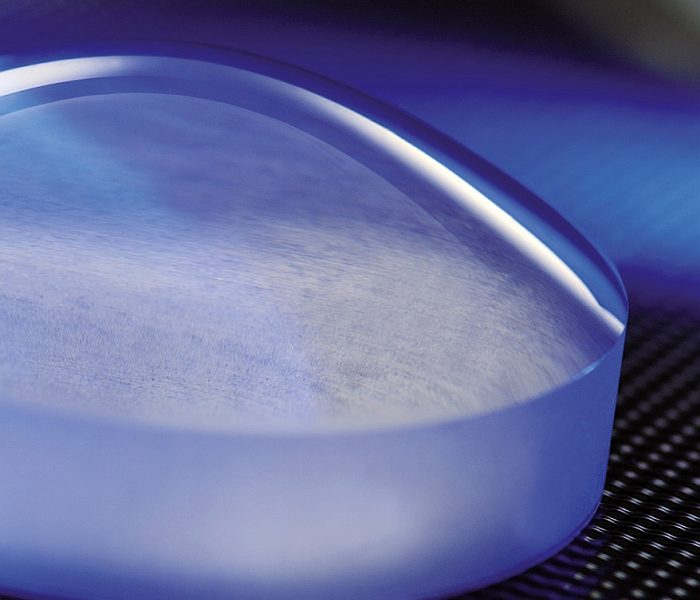

Due to the increasing use of aspheres and free-form optics, for example in lighting or imaging technology, the need for economical manufacturing processes for optics with non-spherical surfaces is growing. The laser ablation and laser polishing of glasses developed at Fraunhofer ILT offers flexible and cost-effective alternatives to conventional methods. Polishing is based on the remelting of a thin surface layer of the workpiece and smoothing of the surface as a result of interfacial tension.

The range of services includes feasibility studies, the development of application-specific laser processes, support in integrating new technologies into industrial manufacturing processes, simulation and modeling, and individual consulting.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT