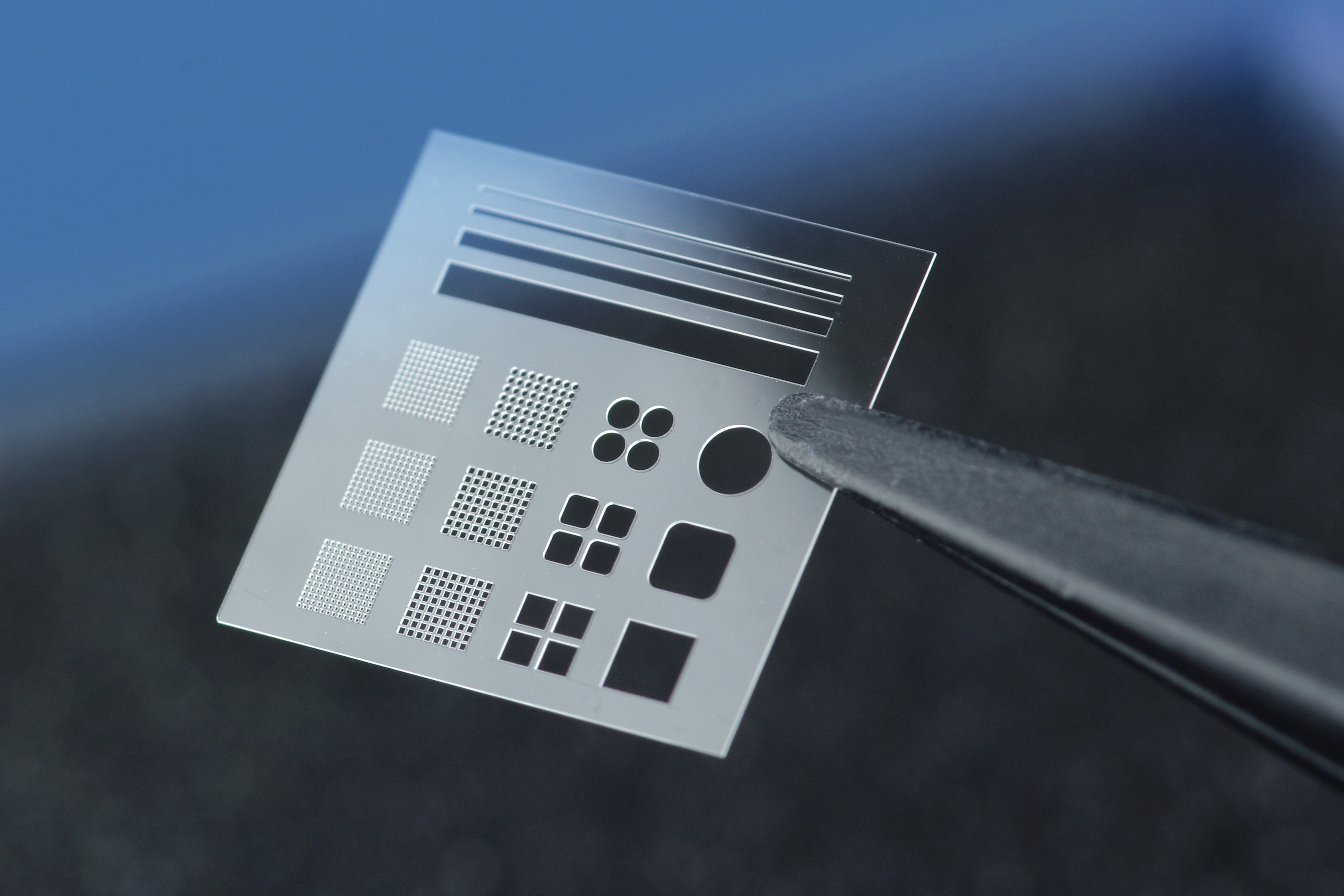

SLE is a two-step process for manufacturing complex 3D components made of glass or sapphire. In the first step, ultrashort pulsed laser radiation is focused into the volume of the transparent workpiece. The pulse energy is absorbed only in the focus volume based on a multiphoton process. The process modifies the transparent material without cracking it, thereby changing its chemical properties. This way, the material can be selectively chemically etched. By deflecting the focus in the workpiece with a microscanner system, the process can modify contiguous areas. These can be removed in a second process step by means of wet chemical etching, making it possible to produce microchannels, shaped holes, structured components and complex, composite mechanical systems.

Fraunhofer ILT, in collaboration with the Chair for Laser Technology LLT at RWTH Aachen University, has demonstrated for the first time that selective laser-induced etching can be used at process speeds relevant to industry.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT