"The processes of producing hydrogen and compressing, transporting and converting it back into electricity or mechanical energy are still far too inefficient," explains Dr. Alexander Olowinsky, head of the Joining and Cutting department at Fraunhofer ILT and organizer of the LKH2.

Increasing the efficiency of hydrogen processes is one of the top themes of the LKH2 and is the common thread running through all the presentations. The variety of topics covered in the almost 20 presentations shows the range of highly efficient laser processes for the entire hydrogen production process chain. The presentation by Robert McConville, principal manufacturing engineer at Hysata Pty Ltd from Unanderra, Australia, near Sydney, will certainly be of particular interest to participants. According to the company, it aims to supply the world's cheapest green hydrogen in the not-so-distant future.

The chances are good, as a spin-off from the University of Wollongong has developed a capillary electrolyzer in which small capillaries distribute the water evenly. This electrolyzer achieves a remarkably high system efficiency of 95 percent (41.5 kWh/kg). The alkaline electrolyzer requires considerably less energy to produce one kilogram of hydrogen than the best commercial water electrolyzers currently available. The efficiency of the Hysata electrolyzer, which has been proven in practice, is above the efficiency target (42 kWh/kg) set by the International Renewable Energy Agency (IRENA) for the year 2050.

Pooling expertise from Germany and Australia

The next step is to start efficient large-scale production as part of the "German-Australian Hydrogen Innovation and Technology Incubator (HyGATE)" funding initiative. Australia and Germany have been building the world's first supply chain for sustainable hydrogen since June 2023. In Aachen, Hysata's lead engineer McConville will also explain the role of German production technology in the entry into the efficient production of electrolyzers. His talk is sustainable in two ways: He is not traveling to Aachen by plane, but is giving his talk online at LKH2 to report on the joint approach. "When we talk about sustainability and the energy supply of the future, we can't send a speaker halfway around the world to give a lecture here," explains Olowinsky.

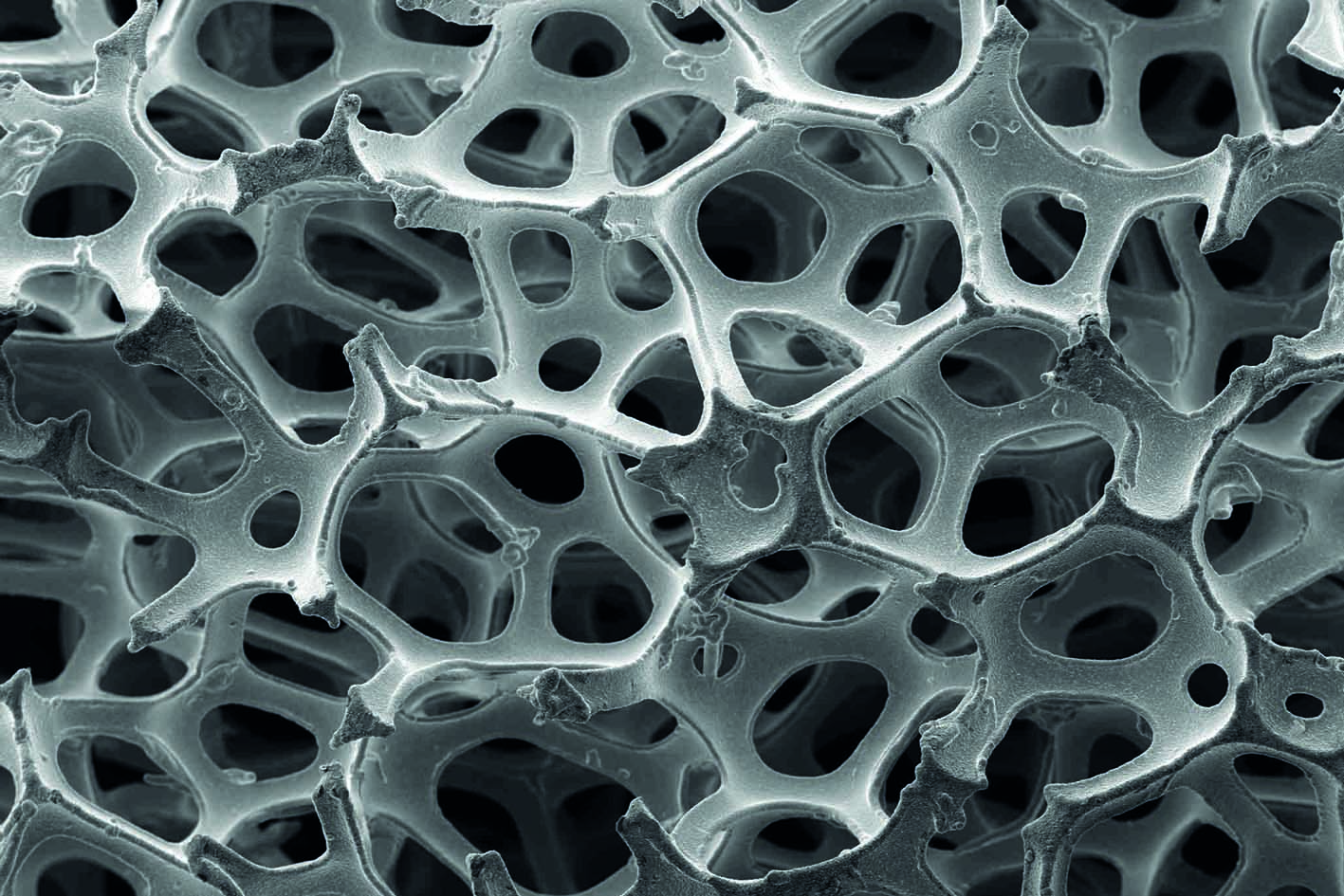

The laser is the focus of McConville's presentation: Fraunhofer ILT is developing laser-based processes and systems in a sub-project on production technology – for example, for processing metal foam electrodes. This development by the Dresden-based Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM increases the reaction surface and thermal conductivity, thereby increasing efficiency.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT