Computer Assisted Manufacturing (CAM) playsan important role in the process chain for laser material processing. Based on a digital model of the part a NC program is generated to control the mechanical and optical axes of the system. For the process of Laser Material Deposition (LMD) Fraunhofer ILT developed the software LMDCAM. This software is a powerful tool path planning tool for component repair and additive manufacturing. It is optimized to work with large data files (e.g. triangulated data acquired by a scanning device).

The user can interact extensively with the software (like CAD data, tool path, etc.) and thus solve complex and individual tasks. After tool path generation the computed machine movement can be validated against collisions or exceeded axis velocities. For this task the software includes a build-in machine simulation tool. A programmable post processor allows for easy export of the the tool paths as an NC program, which also supports multiaxes systems (e. g. robots).

For the process of laser micro structuring galvanometric laser scanners for laser beam deflection and short pulse laser sources are used. Compared to LMD laser micro structuring is a subtractive manufacturing process where the material is ablated locally. Fraunhofer ILT developed the software SliceGen specially adapted to the laser structuring process. A CAD model is filled layer by layer with tool paths. Each layer can be tiled to adapt to limitations of the working volume of the laser scanner. The tiles can be distributed randomly to avoid visible boundaries. The software is also able to generate tool paths for form correction based on measured data. For this application the tool paths for removing the surplus volume are calculated from current and desired topography.

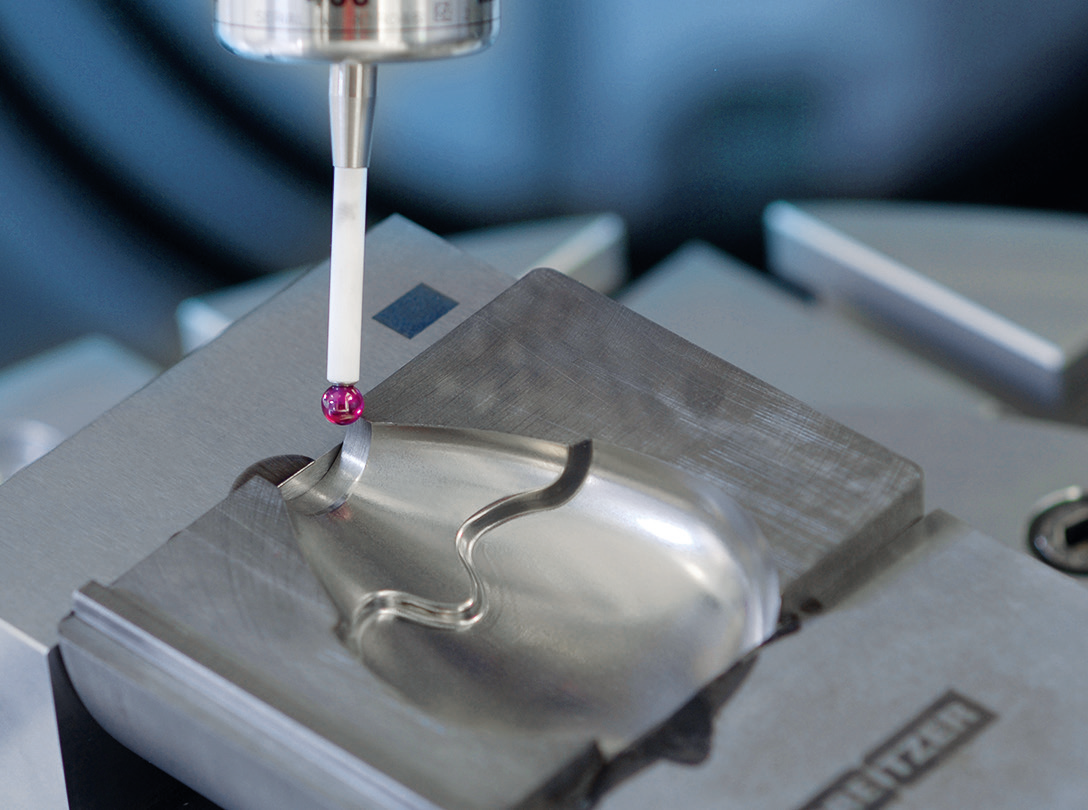

For the process of laser polishing Fraunhofer ILT developed the software TP4 to convert an NC program generated by a conventional CAM software (for finishing milling) into tool paths suitable for laser polishing. Similar to laser structuring, this process also makes use of a laser scanner for fast laser spot positioning. Here the process movement is split into two parts: The fast movement is assigned to the laser scanner while the slow movement is assigned to the slower mechanical axis system (usually a 5-axis system). The software calculates the superposed movement and generates separate NC programs for the laser scanner and the mechanical axes. Machine programming in work piece coordinates is also supported through use of a measuring probe. Several process strategies are implemented in the software to ensure constant process conditions not only on flat but also on curved surfaces.

To fit the requirement for different applications the software can access a database with many process parameters for different materials, applications and kinematics.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT