Ablation and Joining

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyCarboLase – Photonics meets textile engineering

Carbon fibre-reinforced (CFRP) components are normally assembled by fasteners that are glued into the cured and drilled CFRP component. The integration of the fasteners into a textile preform and an additional curing process to produce the final CFRP component can shorten production process chains. This requires high-precision cut-outs in the textile for the fasteners. In the NRW-based project CarboLase, funded by OP.EFRE, laser material processing is integrated for the first time into an automated preforming process. A novelty in the process is the use of the material-friendly ultrashort pulsed laser, which processes the textiles without damaging them thermally. By combining the technologies in a flexible robot cell, just-in-time production of CFRP components with integrated fasteners is now possible independent of component geometry and batch size.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyCutting of Thermoplastic Composites

Fibre-reinforced plastics (FRP), the use of which is becoming increasingly widespread due to their great lightweight construction potential, generate high tool wear during mechanical processing by milling or drilling, which is avoided by non-contact laser cutting. The cut 1 mm thick composite material is made of polypropylene, which is also reinforced with glass fibres.

Structuring of aluminum with a hybrid polygon scanner

The video shows the structuring of an aluminium profile (width 50mm) with a hybrid polygon scanner at a laser power of 2 kW and a scanning speed of 25 m/s. The laser processing enables an increase of the adhesive strength of plastic-metal connections.

The polygon scanner beam deflection system was developed within the project "ComMUnion", which was funded by the European Commission.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyFlexible production cell for hybrid joining

In the FlexHyJoin project, a fully automated process was developed for joining TP-FRP with metal in multi-material construction. With induction and laser welding, two processes were combined in a fully automated production cell that complement each other perfectly. By implementing innovative surface structures in the metal, which are created by means of laser radiation, it is possible to achieve a positive fit and thus an optimized adhesion for hybrid components, without any additional materials such as adhesives. Due to a high degree of automation and a considerable reduction in cycle time, FlexHyJoin will advance the extensive use of hybrid components in automotive series production.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyTechnology Demonstrator Polymer Processing

With the demonstrator the various applications of laser technology in the processing of plastics can be demonstrated:

- Cutting of PMMA in different material thicknesses (0.3, 1 & 2 mm) with a CO2 laser

- Removal of PMMA in the form of microfluidic structures with a CO2 laser

- Absorber-free laser transmission welding of PMMA with diode laser radiation (λ=1660 nm)

- Laser microstructuring of stainless steel (1.4301) with fiber laser radiation (λ=1064 nm)

- Joining of a plastic-metal hybrid connection with diode laser radiation (λ=940 nm)

All laser-based processes are characterized by a high degree of flexibility, an energy deposition that can be precisely adjusted in terms of location and time, and a high degree of automation.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyQuasi-Simultaneous Irradiation during Laser Transmission Welding of Absorber-Free Plastics

The challenge in laser transmission welding of two optically identical plastic parts lies in the selective heating of the joining area in order to avoid component distortion and burns on the irradiated surface. As a rule, a highly focusing fixed optic is used for this, which, however, can only be guided over the component with contour accuracy up to a certain speed due to inertia. Scanners offer higher dynamics, however, with which the beam cannot be focused sufficiently strongly. This restriction can be overcome by irradiating the welding contour quasi-simultaneously and thus achieving selective heating of the joining area by heat accumulation.

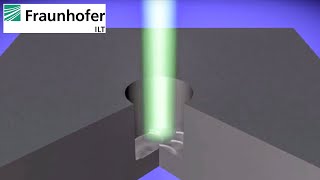

Functional principle of the Fraunhofer ILT helical drilling optics

With the helical drilling optics, precision holes with diameters from a few µm to 300 µm can be achieved in metallic and non-metallic materials up to 3 mm in thickness. The conicity of the micro holes is adjustable for various applications such as micro filters. Furthermore, micro-crack-free precision cutting of sapphire and chemically hardened glass is possible. The combination of the helical drilling optics with an ultra-short pulsed laser beam source allows a nearly material independent use of the system.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyLaser-Beam Drilling of a Jet-Engine Nozzle

Approximately 74,000 holes with a diameter of 1.5 mm shall be drilled into the primary nozzle of a jet engine by using laser radiation. The drilling technique trepanning is used. The nozzle has a diameter of about 900 mm and a length of about 350 mm. The holes will be drilled distributed into 2048 rows, each with 36 holes around the circumference of the nozzle. The nozzle with a material thickness of 1.5 mm is made of titanium alloy Ti 6-2-4-2.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyStrategies for Drilling with Laser Beams

Depending on the component thickness and the required quality (precision) and productivity (drilling time), holes with diameters from 1 µm up to several millimeters can be achieved by using single-pulse drilling, percussion drilling, trepanning or helical drilling. The single pulse drilling can be performed "on-the-fly", so that up to 300 holes per second with a diameter of e.g. 60 microns in 1 mm thick material can be achieved. Larger hole depths can be achieved by using percussion drilling. For hole diameters larger than 300 microns, trepanning is used where a relative movement between the workpiece and laser radiation occurs. Holes with high precision concerning geometry and high metallurgical quality are achieved by using helical drilling.

Functional principle for precise helical cutting

The precise cutting of dielectric materials such as glass, ceramics, sapphire, etc. poses a special challenge to production engineering due to the extreme material properties in some cases. The quality of the cutting edges is critical for the function of precise mechanical components. By means of helical cutting, especially with ultra-short pulsed beam sources in the femtosecond and picosecond range, these materials can be processed flexibly and with high quality. Here, the laser radiation is set into a circular oscillation and thus not only cuts the material but also reworks the cut edge based on vaporization. With the helical drilling optics based on a rotating Dove prism and a frequency-doubled ps-laser, precision cuts are produced in ceramic, silicon and sapphire of different thicknesses.

ultraSURFACE – first application tests for laser structuring with the developed MultiBeam optics

Funded by the European Union, the ultraSURFACE project focuses on optimizing optical systems with dynamic 3D applicability and on developing strategies for laser-based production processes with high-throughput. In the project, Scientists and industry partners are developing two new optical designs which allow users to adapt laser beam manipulation individually and to increase throughput by a factor of ten compared to conventional processes. The video shows first application tests for laser structuring with the developed MultiBeam optics, which were integrated into a machine tool at Unitechnologies.

Laser Ablation of an Arbitrary Geometry on ZERODUR®

With pulsed CO2 laser radiation (Q-Switch), ZERODUR®, a glass ceramic material, can be precisely processed. The material removal in the example shown was realized with the following parameters:

- Repetition rate ≤ 150 kHz

- Pulse peak power about 20 kW

- Pulse duration about 300 ns

Laser ablation and laser polishing of glass offers flexible and cost-effective alternatives to conventional manufacturing processes. Laser-based ablation processes can be used both for shaping and for shape correction polishing (Laser Beam Figuring).

Diameter of the machined geometry: 50 mm

Laser Ablation of an Arbitrary Geometry on Fused Silica

When fused silica is processed with CO2 laser radiation, the laser radiation is absorbed in a thin surface layer of the workpiece so that the temperatures can be raised up to the material’s evaporation temperature. If the fused silica is heated locally by the interaction with the laser radiation above the evaporation temperature, material can be ablated. Pulsed CO2 laser radiation (Q-switch) with these parameters was used for the laser process shown in the video:

- Repetition rate ≤ 150 kHz

- Pulse peak power about 20 kW

- Pulse duration about 300 ns

- 0.1 to 50 µm ablation depth per layer

- 1 to 3 mm3/s Ablation rate

Sample size: 20 mm x 20 mm x 5 mm

Laser Ablation of a Lens Array on Fused Silica

With the laser process shown in the video an arrangement of defined lens geometries on fused silica was generated. The material was ablated with pulsed CO2 laser radiation (Q-switch) and these parameters:

- Repetition rate ≤ 150 kHz

- Pulse peak power about 20 kW

- Pulse duration about 300 ns

- 0.1 to 50 µm ablation depth per layer

- 1 to 3 mm3/s Ablation rate

Laser ablation offers the advantage of contactless processing. High costs for grinding tools are therefore avoided by an almost wear-free tool during laser ablation. Local ablation can generate not only free-form surfaces but also steep flanks for structuring the back of optics, for example to reduce weight.

Sample size: 90 mm x 90 mm x 4 mm

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyLaser-based micro joining for a wide range of connections

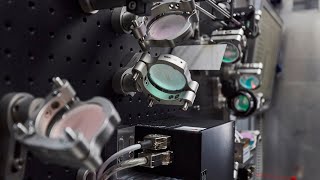

From medical technology and hybrid joints for lightweight applications to battery and fuel cell production for the future of mobility: Scientists from the Micro Joining Group at Fraunhofer ILT are developing a wide range of joining techniques for various applications. Here, laser technology allows high-precision welding with minimal thermal stress and the generation of the smallest seam structures. Fraunhofer ILT possesses cutting-edge equipment and a spectrum of different laser beam sources to develop customized solutions for industry and science.

Laser Impulse Metal Bonding – LIMBO

Increasing demands in high-performance electronics and electromobility require more and more components that are highly robust and thermally stable. Laser Impulse Metal Bonding (LIMBO) enables a reliable and high-temperature stable joint between thick copper connectors with thicknesses above 200 µm and thin copper metallizations with thicknesses below 100 µm on sensitive substrates.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyStifterverband Prize for Multi-beam Laser Processing

The ultra-short pulse laser is seeing ever wider acceptance among industrial users as a tool for precision manufacturing. In particular, these advances are due to new developments or technological progress in system technology, which increase productivity considerably. Increasing productivity significantly was also the goal of a team from industry and research, which was awarded the Science Prize of the Stifterverband for Collaborative Research at the annual conference of the Fraunhofer-Gesellschaft on October 9, 2020. The team has developed a technology in which a laser beam is split into up to 16 partial beams. That means there are 16 tools controlled in parallel and individually to produce functional surfaces.

Privacy warning

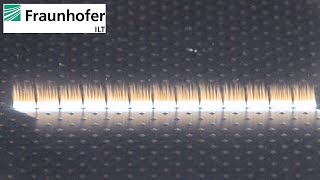

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyMultiFlex – Making ultrafast lasers faster

Ultrafast lasers with pulse durations down to the femtosecond range are known for their ultra-precise ablation and cutting results, but also for their long process durations. Funded by the EU, the MultiFlex project aims to make material processing with ultrafast lasers up to a hundred times faster by using a high-power USP laser with more than 1kW average power. A selective multibeam approach is used to deliver the power efficiently to the workpiece.

- More Information: https://multiflex-project.eu/

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyPhotonic process chain with USP structuring, cleaning and polishing.

Photonic Process Chain for efficient ultrashort pulse surface texturing

Industrial laser texturing is currently still dominated by nanosecond lasers. New approaches show that by means of ultrafast laser sources the productivity of nanosecond lasers is exceeded by a factor of 4 while maintaining the same quality. A removal rate of up to 20 mm³/min with a surface roughness of Ra = 1.5 µm can be achieved. Even roughnesses of < 0.5 µm can be achieved with a ablation rate of up to 10 mm³/min. The photonic process chain shows that with the universal tool of an ultrafast laser, subsequent processes such as cleaning and polishing can also be carried out in the same machinery without time-consuming set-up or re-clamping of the workpiece.

The videos on this website are subject to copyright. All rights are reserved, whether in whole or in part, in particular the rights of translation, reprint, reuse of images, screenshots, recitation, broadcast, reproduction on microfilm or otherwise and storage in databases. The reproduction of this publication – here one video, several videos or parts thereof – is only permitted in accordance with the provisions of the Copyright Act of September 9, 1965, as amended, and requires the prior permission of the Fraunhofer Institute for Laser Technology ILT, Aachen, Germany. Violations are punishable under copyright law.

The use of general descriptive names, registered names, trademarks, etc. in these publications does not imply, even without express declaration, that these names are excluded from the relevant protective laws and regulations and are therefore free for general use.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT