In modern production, especially in the automotive industry, blanks from coils have to be cut both precisely and efficiently, and the requirements are becoming more and more demanding. Traditional methods, such as punching, are reaching their limits, especially when it comes to flexibility and resource conservation in production. In addition, industry needs to reliably and safely monitor continuous production processes to avoid expensive system downtimes and production losses. Malfunctions caused by cutting interruptions, for example, can be detected and avoided at an early stage with additional sensors and control mechanisms.

As part of the joint project DIPOOL (Digital Process Online Optimizer for Intelligent Laser Machines), the Fraunhofer Institute for Laser Technology ILT and its project partners are developing solutions to improve the efficiency and safety of laser cutting and welding processes. DIPOOL is funded by the German Federal Ministry of Education and Research (BMBF) and combines the expertise of leading industry and research partners to develop pioneering solutions for Industry 4.0.

“The project aims to use artificial intelligence and minimally invasive laser modulation to optimize process monitoring and control in sheet metal processing, with a particular focus on thin sheet metal and laser blanking,” says Dr. Frank Schneider, DIPOOL project manager and cutting group leader at Fraunhofer ILT. “These technologies make it possible to detect process deviations in real time and make immediate adjustments to sustainably increase production reliability and speed. With the DIPOOL project, we really are setting new standards in sheet metal processing.”

The functional principle of the monitoring system is based on a “minimally invasive” laser modulation pattern (MILM). Minimal disturbances are imposed on the machining process, to which the process continuously responds with particularly characteristic, condition-dependent signals. Artificial intelligence (AI) can analyze these patterns particularly well.

Cooperation between Fraunhofer ILT and Dreher Automation

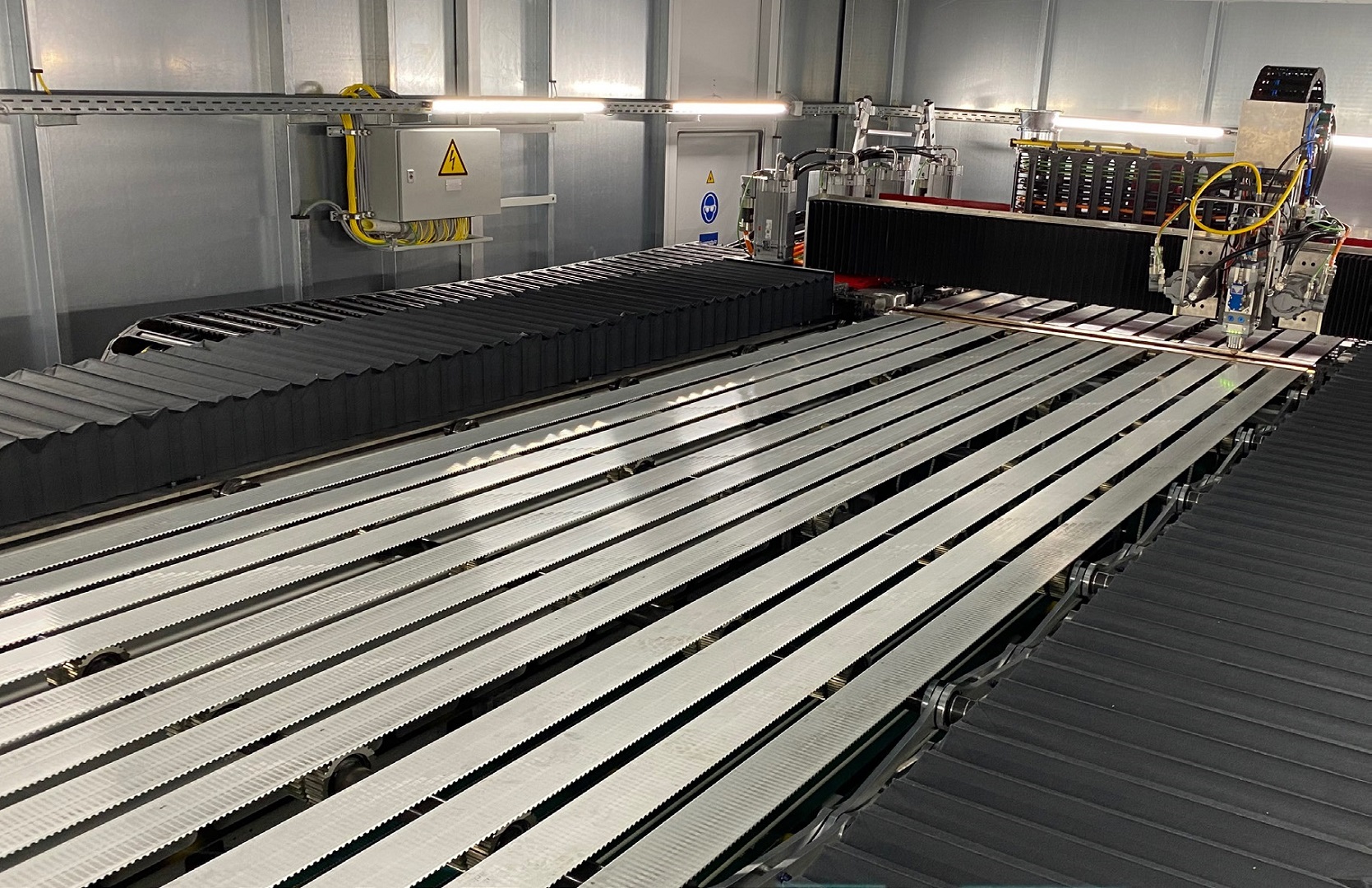

Automatic-Systeme Dreher, Fraunhofer ILT and the pilot customer have cooperated on building an industrial-scale laser blanking demonstrator system and integrating system monitoring with AI and MILM. For this pilot customer, the Aachen-based institute has been developing the process over many years.

Dreher Automation is an experienced specialist for automation systems in the field of forming processes and contributes its expertise in the development of high-precision machine solutions. “By combining a new type of system design, the high-speed cutting process developed by Fraunhofer ILT and innovative process monitoring, we are now able to machine blanks dynamically with extremely short cycle times,” explains Schneider.

Fraunhofer ILT and Dreher Automation will be presenting the demonstrator system at booth 27-H82 at EuroBLECH 2024. The system, which will be used to process cold-rolled strip products, among other things, is specially designed to maximize process reliability when processing coils. The AI-based systems analyze the process signals in real time and detect even the smallest deviations before they lead to problems. MILM ensures that the cutting process remains continuously stable, an advantage that minimizes scrap rates and significantly increases the overall productivity of the system.

“The new concept of overlapping work areas of two processing heads with continuous belt transport in the system enables maximum flexibility and resource-efficient production,” explains Hasan Sarac, managing director of Automatic-Systeme Dreher. “This means that each laser can process exactly what is required. This way, we can optimize nesting and process large components. This is a decisive advantage that makes manufacturing in automotive production more cost-effective."

Outlook and next steps

The demonstrator system implements the findings and results of the DIPOOL project. The design of the system is primarily aimed at automotive production, in particular the cutting of structural components and other sheet metal parts from coils. This saves immense costs: Because laser blanking does not require expensive tools, it saves costs there as well as makes both storage and maintenance unnecessary. And downtimes due to tool changes are also a thing of the past.

The test runs demonstrate the advantages of the new system design and continuous production from the coil, which optimizes nesting and saves on material, one of the key levers for the system’s resource efficiency. Higher productivity, reduced scrap rates and flexible adjustment of the cutting contour in tryout production – all decisive advantages.

“Our collaboration with Fraunhofer ILT as part of the DIPOOL project impressively demonstrates how mechanical engineering and innovative technology can go hand in hand to create a new benchmark for the industry,” summarizes Hasan Sarac.

After the presentation at the Euroblech trade fair, the results of the DIPOOL project will flow into the first industrial implementation. In cooperation with the BILSTEIN GROUP as a pilot user, optimizations and extensions will then follow that are necessary for use in series production.

Visit us from October 22 to 25 in Hanover at the booth of Automatic-Systeme Dreher GmbH, booth number 27-H82, to learn more about the demonstrator system and DIPOOL. The Fraunhofer ILT will also be demonstrating the laser processing of bipolar plates for hydrogen technology.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT