Transporting heavy goods, particularly by truck, significantly contributes to global CO2 emissions. In Europe, road freight transport accounts for around 30% of emissions in the mobility sector. So far, fossil fuels have dominated, as the batteries required in electric solutions add an enormous amount of weight, which in turn reduces the payload. In addition, the associated requirements for charging currents and charging times significantly restrict use in heavy-duty transportation applications. Fuel cells offer a promising alternative, as they combine high energy density with fast refueling.

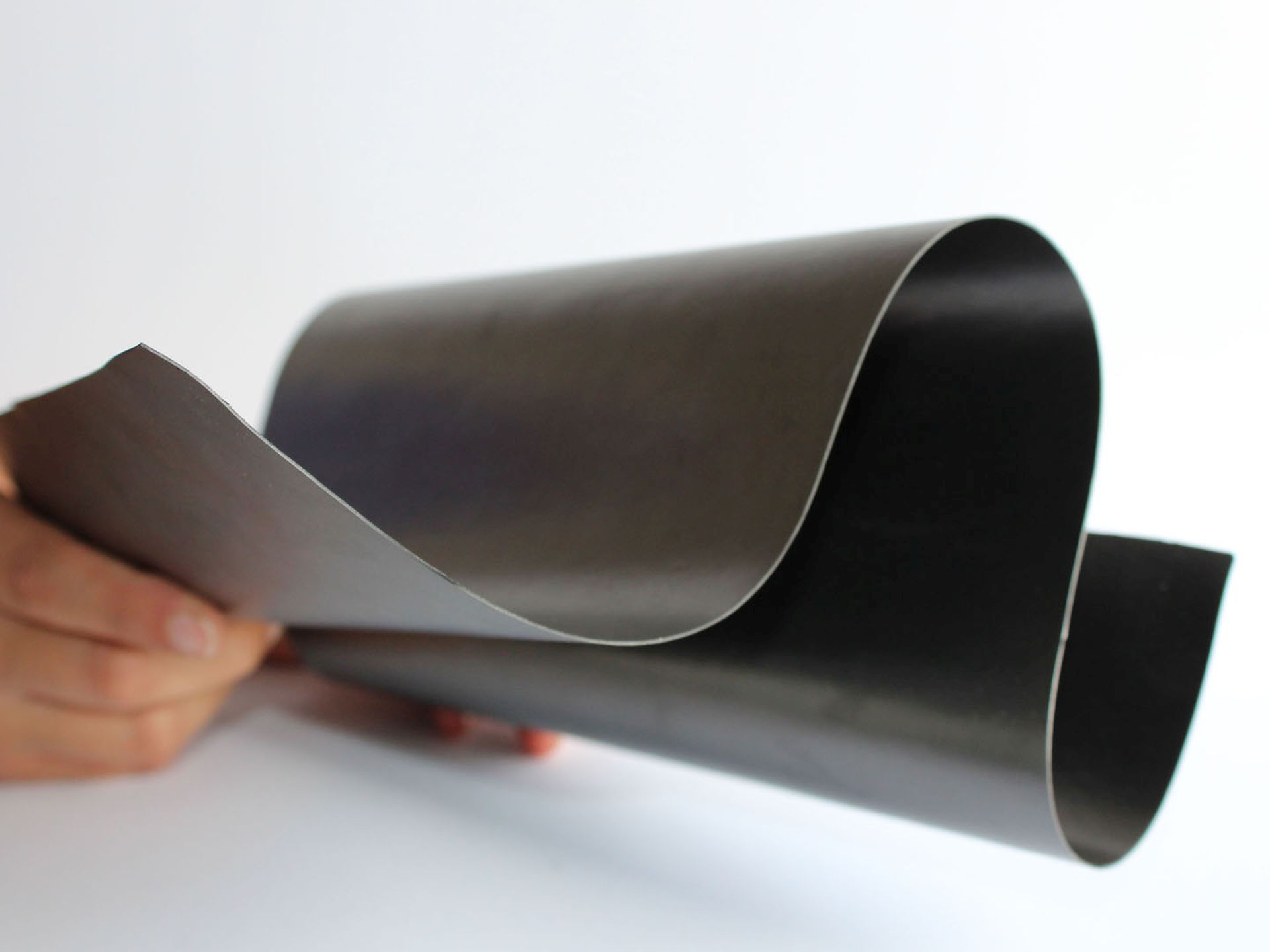

Fuel cells for heavy-duty transportation must be particularly robust and durable, as they are used under challenging conditions. Temperature fluctuations, mechanical stress and corrosive environments place high demands on the materials and processing of the individual components. This is where the HyCoFC project comes in: By combining a metallic carrier film with a conductive compound film, the project is uniting the advantages of both materials. The large-format hybrid compound bipolar plates provide good electrical conductivity, mechanical stability and excellent corrosion resistance – properties that are crucial for heavy-duty transportation. These plates are designed to improve the service life of fuel cells and reduce production costs at the same time.

In addition, the modular structure of the fuel cell stacks can be scaled for different areas of application, from commercial vehicles to ships and even stationary applications. “This versatility makes the technology an ideal component for the energy transition in the mobility sector,” explains Friederike Brackmann from the Joining and Cutting Department at the Fraunhofer Institute for Laser Technology ILT.

Science and industry: researching together

The HyCoFC project is being funded as part of the “Energie.IN.NRW” innovation competition, which is part of European regional funding. The project runs from June 15, 2024 to June 14, 2027. With a total funding volume of around 3 million euros, the project is supported by a strong financial basis that enables the partners from science and industry to carry out extensive research and development. In addition to Fraunhofer ILT, Fraunhofer UMSICHT is involved on the scientific side. The industrial companies involved are project coordinator thyssenkrupp Steel as well as FEV, Schepers and Cleanlaser.

thyssenkrupp Steel is producing the metallic carrier film with a chrome layer to improve the corrosion resistance and the bonding properties to the compound film. Fraunhofer UMSICHT is specifically controlling the electrical and thermal conductivity of the compound film by selecting specific materials and fine-tuning their composition. As part of the project, Fraunhofer ILT is dedicated to advancing laser-based technologies for the production and functionalization of hybrid compound bipolar plates. Friederike Brackmann is primarily concerned with the joining technology challenges, while her colleague Tobias Erdmann from the Surface Technology and Ablation Department is responsible for the selective decoating of the compound elements using laser radiation and the final electrochemical characterization of the hybrid stack. Using various laser techniques, they are introducing microstructures into the components in order to improve the bond between the metallic and polymer-based components. In addition, they are developing processes to remove material layers, which maximize the electrical conductivity of the bipolar plates.

In the Fraunhofer ILT's in-house Hydrogen Lab, researchers will find an infrastructure extensively equipped and specifically geared towards developing and optimizing hydrogen technologies. State-of-the-art laser technology test facilities and test benches are set up on an area of 300 m², making it possible to test and develop individual production steps as well as complete process chains and specific industrial applications under realistic conditions.

Brackmann is testing, for example, how the bipolar plates can be joined in a hydrogen-tight and reproducible manner using laser welding. Erdmann is investigating how the contact resistance between the bipolar plate and the gas transport layer can be optimized. “We expose the conductive graphite filler material in the contact area with the gas transport layer,” explains the researcher. “Unlike mechanical grinding processes, ultrashort pulsed laser radiation can selectively remove the plastic without damaging the filler material.”

Future prospects for sustainable transportation

The combination of innovative materials and production methods not only meets the requirements of heavy-duty transportation, but also sets new standards in fuel cell technology. The hybrid compound bipolar plates developed have the potential to significantly increase the service life of fuel cells and expand their range of applications. From heavy-duty vehicles to maritime applications and stationary systems, the project will open up a wide range of perspectives for a climate-friendly energy supply.

“Fraunhofer ILT is playing a central role in the development of hybrid compound fuel cells by providing pioneering laser manufacturing technologies that significantly improve both the efficiency and longevity of these innovative energy systems,” explains Friederike Brackmann.

The close cooperation between the project partners and the support from funding programs provide the basis for successfully putting the results in practice. “A particular focus at HyCoFC is on developing processes that enable economically scalable and cost-efficient production in large quantities,” says Tobias Erdmann. "We are focusing on the roll-to-roll process, which ensures continuous and high-quality processing of the materials. We want to implement and test this next.“

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT