LAR3S - Laser Generated Three Dimensional Photonic Components

Fraunhofer Max Planck Cooperation Program: The focus of the collaborative project LAR3S is the research and implementation of novel photonic structures as well as the necessary manufacturing processes

Photonics is one of the most challenging fields of development with a wide range of applications for the realization of new computer systems, state-of-the-art ultrahigh-resolution measurement technology, mobile sensor technology and material sciences. This requires, among other things, the use of modified electromagnetic waves or single photons, which require suitable beam guiding and shaping elements, optical storage devices and highly selective spectral filters. While novel photonic structures are constantly being conceived and simulatively researched for the progress of these elements, their fabrication is still based on established fabrication methods, which are severely limited with respect to their geometrical freedom and are only suitable to a limited extent for this purpose.

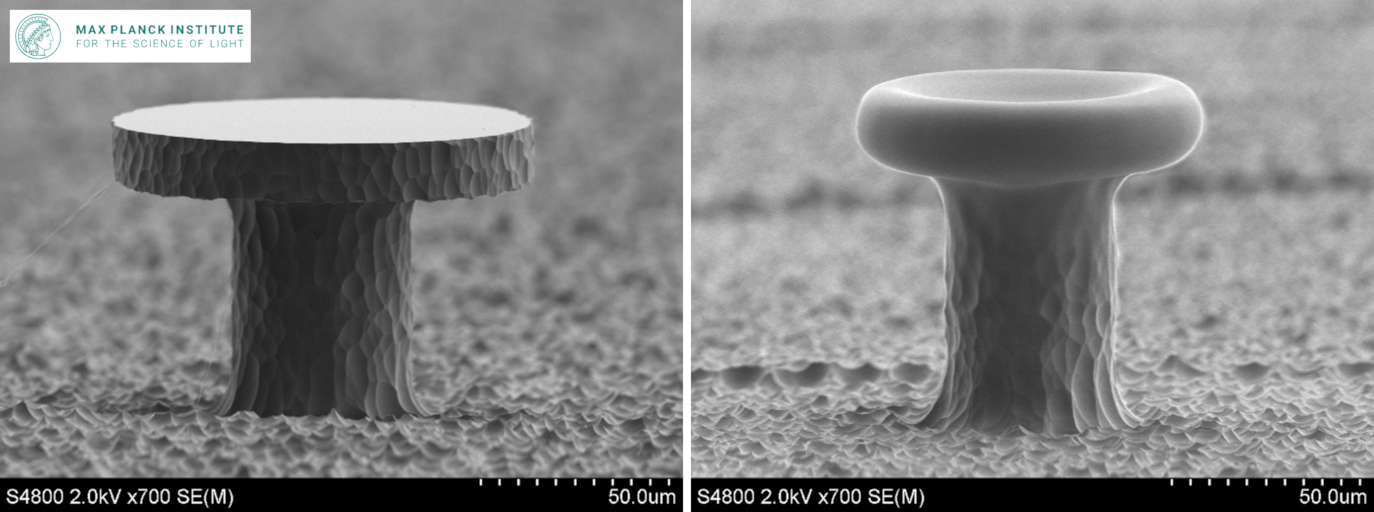

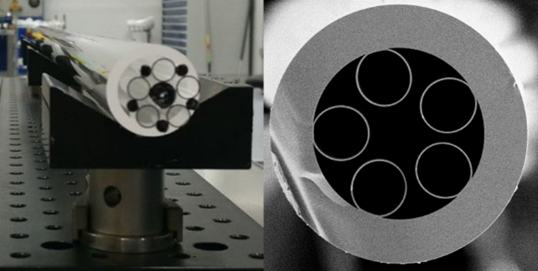

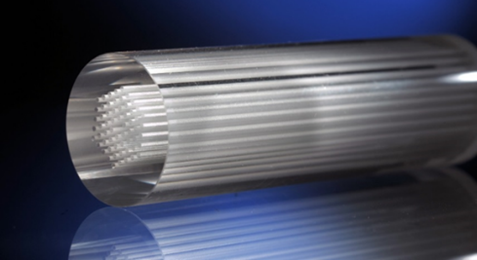

The aim of this project is to research and implement novel three-dimensional photonic structures, for example geometrically twisted photonic crystal fibers or non-orientable microresonators. At Fraunhofer ILT, the methods required to manufacture such structures are being developed based on selective laser structuring and laser modification processes. It is only through the use of micro- and nanoscale laser-based manufacturing processes that the production of such components becomes possible at all. In particular, the two manufacturing processes inverse laser beam drilling (ILB) and selective laser-induced etching (SLE) offer the required geometric degrees of freedom for the generation of three-dimensional photonic components.

Duration of the project

1.3.2022 - 31.7.2025

Project volume

2.2 million euros

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT