Joint optimization increases efficiency and precision

Fraunhofer ILT contributed its extensive expertise in the field of laser-based manufacturing processes and brought its comprehensive infrastructure and specialized laboratory facilities to the project. Thanks to its decades of experience in process and component development for LMD, the institute made a decisive contribution to optimizing the process parameters for processing various materials and ultimately transferring the new technology to the industrial pilot customer toolcraft AG. This included adjusting the laser parameters, fine-tuning the powder feed and optimizing the motion control of the CNC machine.

"Optimizing the heat input is a critical aspect of the EHLA3D process," explains renowned materials expert Min-Uh Ko. "The feed rate and powder gas jet play a crucial role in controlling the heat that is introduced into the material. By adjusting the feed rate and powder mass flows, we can precisely control the heat input, reduce the heat-affected zone and ensure uniform coating quality."

According to Johannes Finger, the high build-up rate is a significant advance. "By using high feed rates and an optimized powder feed, we can achieve a considerably improved efficiency of the material application at the same or even higher precision. The build-up rate with HS-LMD can thus be significantly increased, which enhances the overall efficiency of the production process."

Repair and coating of high-performance components

The repair and maintenance of high-quality tool and machine parts exposed to high loads during regular operation was one of the project objectives. The partners were able to achieve this with the adapted EHLA3D technology. In addition, the EHLA3D technology was successfully used to coat wear parts, which significantly improves the service life of these components. As it can now apply wear-resistant coatings precisely and efficiently, EHLA3D has become a cost-effective solution for extending the service life of components in various sectors, including mining and heavy industry.

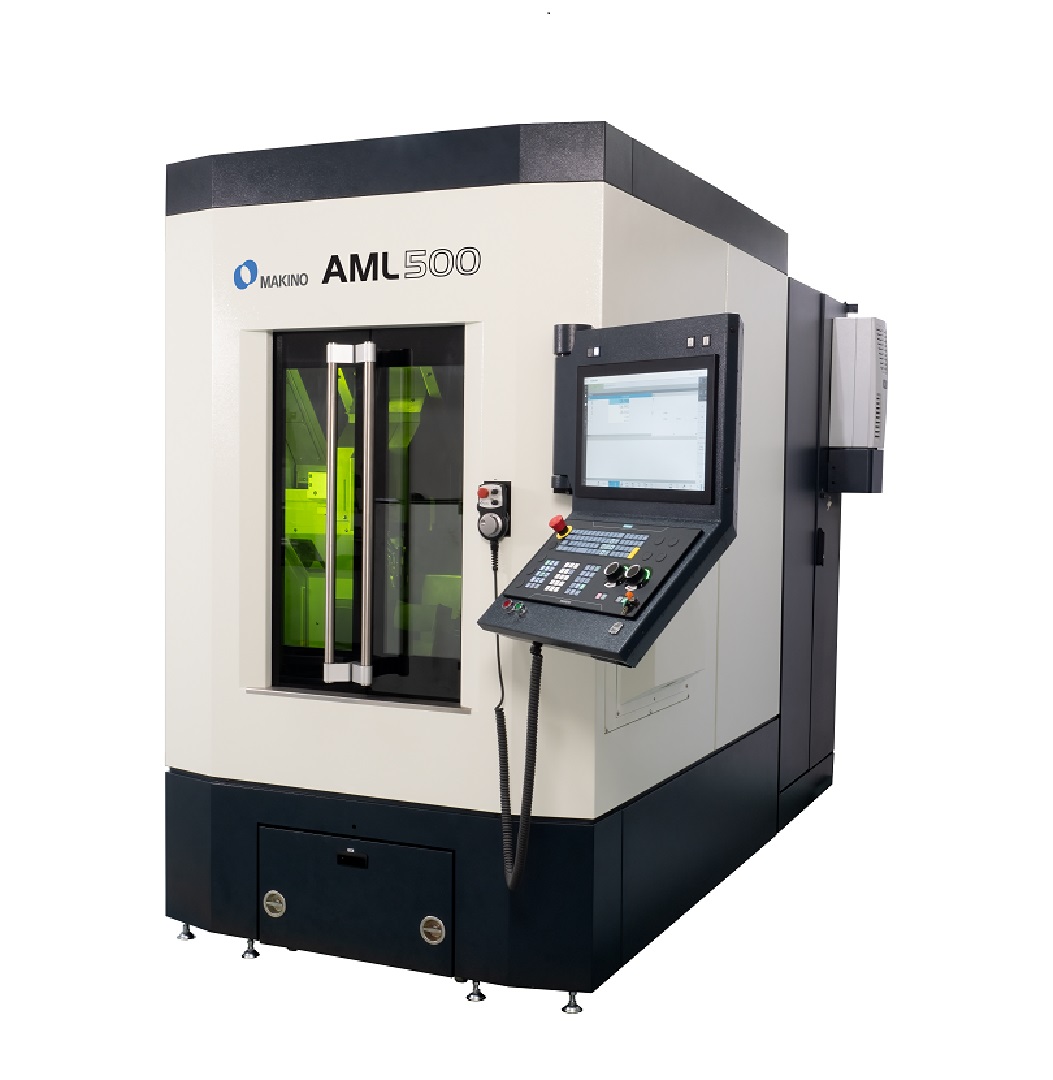

The fact that Makino was able to implement the results so quickly in the new AML 500 processing machine shows, on the one hand, how flexible the machine manufacturer's CNC systems are. On the other, the practical applications also show that the EHLA3D technology is not just a theoretical concept, but an advanced, robust and industrially applicable technology that offers significant advantages in terms of cost, efficiency and performance. The collaboration between the industrial customer and Fraunhofer ILT has, thus, led to tangible improvements in manufacturing technology that go far beyond the laboratory environment.

A key aspect of future developments will be to identify and validate new areas of application for the EHLA3D process. Since the material systems that can be processed have become so flexible, this extended EHLA process can now be transferred to applications that could not normally be investigated since the LMD process has such limitations. This applies in particular to applications with multi-material systems and the printing of fine structures.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT