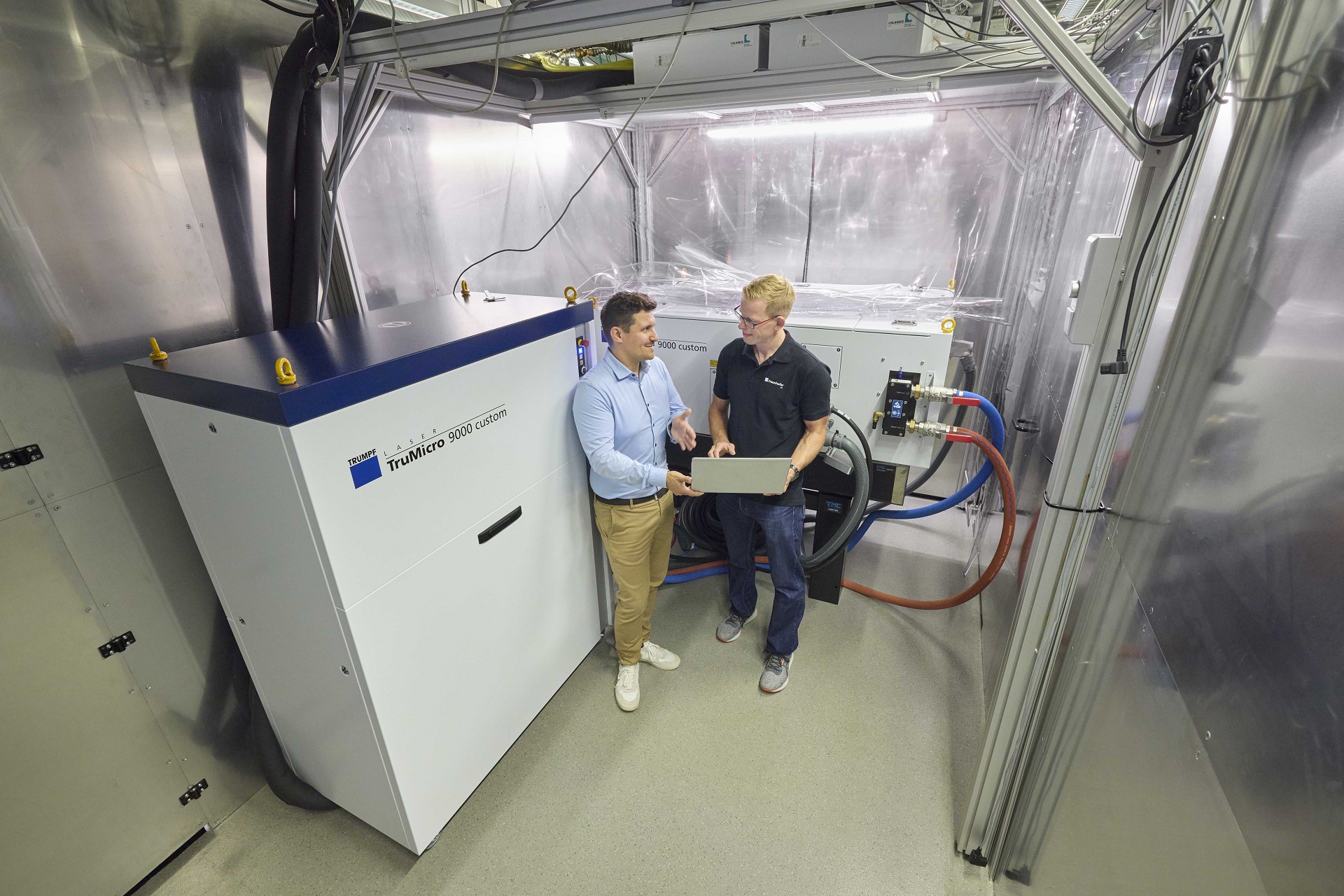

“In the Fraunhofer CAPS cluster, we want to clarify how high-power beam sources can expand the range of applications for USP laser processes,” explains Dr. Dennis Haasler, leader of the group Micro- and Nano Structuring at Fraunhofer ILT. His team will systematically examine this question over the next few months with appropriate experiments. The focus will be on a new USP laser beam source from TRUMPF with an average output power of 1 kW.

As part of a bilateral cooperation, the company is providing Fraunhofer ILT with the new TruMicro 9000, a system designed for industrial applications. Since it provides power into the kilowatt range, this beam source offers many times the average power of the currently most powerful USP lasers for industry. Its pulse energy of 10 mJ also significantly exceeds the previously available level. Indeed, the system has the potential to trigger a productivity boost in USP material processing that many users are waiting for: it has a pulse duration of less than 900 fs, numerous burst options and a very high beam quality of M² < 1.3 – combined with high flexibility at different operating points and the operating standards familiar from TRUMPF industrial lasers. “For the first time, we have a kilowatt beam source that performs like established industrial USP lasers in the 200 W class,” explains Haasler. He and his team will now evaluate how the high-energy laser pulses can be used for industrial manufacturing and finishing processes.

High performance based on a combination of proven technology components

“By combining tried-and-tested technology components in the amplifier chain, we have succeeded in significantly increasing both the maximum individual pulse energy and the resulting average power,” reports Steffen Rübling, product manager for the USP lasers in the TruMicro family at TRUMPF. According to Rübling, the new beam source achieves the typical USP laser beam quality despite its impressive output because the development team was able to draw on a wealth of experience: TRUMPF offers USP lasers of various power classes, each of which is based on different amplifier technologies, including fiber, disk and slab amplifiers. In addition to this technological diversity within their portfolio, the team also benefited from the knowledge gained from component development for continuous wave (cw) and short pulse lasers. For example, the main amplifier of the new TruMicro 9000 – a so-called multi-pass cell – was originally used to amplify nanosecond pulses in the power range of 3 kW. The transfer of such tried-and-tested technology modules to the USP beam source has ensured that it meets industrial requirements straight away. With this stable beam source, Fraunhofer ILT can now explore its application potential.

It depends on the right process strategies

The ILT team will focus on process control strategies and system designs that can be used to optimally utilize the high average power for processing the respective workpieces. Several test setups are available in the Fraunhofer ILT laboratory for this purpose, which the team can use to direct the high power and energy input of the beam source onto the component surfaces for effective and gentle processing. A key advantage of USP laser processes comes into play here: Although their femtosecond or picosecond pulses concentrate a great deal of energy, the thermal load on the material remains minimal thanks to their short duration.

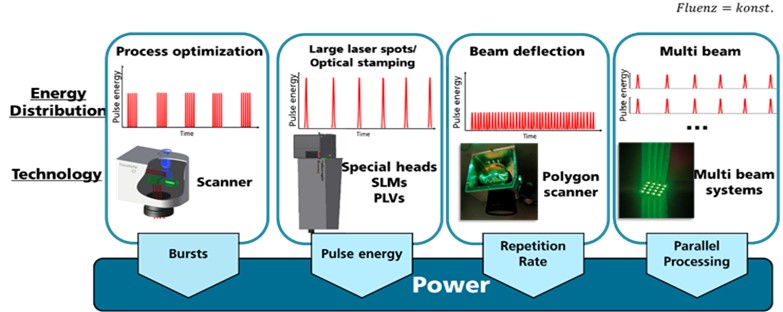

As the new system has a power level of 1 kW and high pulse energy, beam splitting and beam guiding strategies that promise greatly increased productivity through the parallelization of the machining processes are necessary. To prove this, Haasler's team will be relying on the four system technology approaches shown schematically in Figure 4: The simplest approach is the burst mode that can be implemented with conventional galvo scanners. Here, the high energy of the femtosecond pulses is distributed over up to eight individual pulses. The researchers will also be using special system technology and optical strategies for beam shaping and ultrafast beam deflection or for the parallelization of machining processes. “We need the different approaches in order to find out which strategy we can use to achieve the highest productivity for the respective industrial application,” explains Haasler. For example, a different system technology is required for the selective ablation of polymer layers from compound bipolar plates than for the point-by-point removal of active material layers on battery electrodes for their contacting or for the micro structuring of metal surfaces.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT