The Fraunhofer Institute for Laser Technology ILT is an experienced partner for companies in the energy sector looking for innovative solutions. The institute has powerful technologies at its disposal to make products and processes more economical and sustainable.

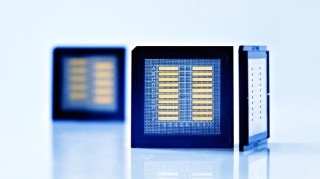

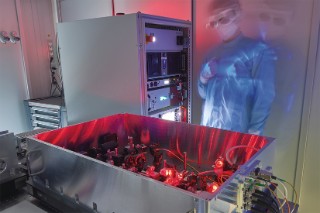

In the field of renewable energies, Fraunhofer ILT advances process technologies to improve the efficiency and performance of photovoltaic and solar thermal systems. One of the technologies developed by the institute is the laser structuring of solar cells to increase light absorption and efficiency. Fusion research is a strategic topic: Here, Fraunhofer ILT is concentrating in particular on developing high-energy laser beam sources and optical systems for inertial confinement fusion. To this end, the institute has networked with European and transatlantic partners.

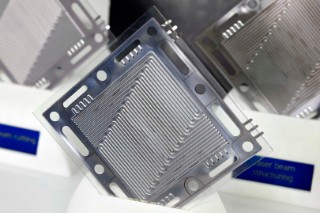

For many years, Fraunhofer ILT has been optimizing conventionally operated energy systems such as generators and turbines. Lasers can be used to process parts and components precisely and quickly. Whether cooling channels created by laser drilling, turbine components repaired by additive manufacturing or components provided with special coatings, laser processes can be used to increase the efficiency and performance of turbines and reduce maintenance costs.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT