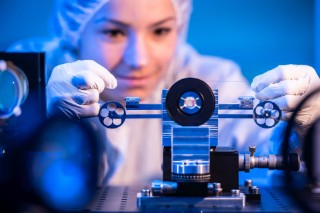

Thanks to synchrotron radiation, welding processes can be observed in greater detail than ever before – live and in real time! Researchers from Fraunhofer ILT and RWTH Aachen University – Chair for Laser Technology University are working at DESY to make vapor capillaries, melt movements and defects visible. Their findings optimize battery and microelectronics production and pave the way for the development of new materials.

more info Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT